How to Reverse Engineer with Split Bend

|

Contents |

How to Reverse Engineer Using Split Bend

|

The Split Bend feature allows you to accurately measure bends that equal or exceed 180 degrees. |

STEP 1: Enter PART SETUP Data

|

Enter the Part Setup data for the new part. Especially enter the DEFAULT RADIUS. (You can measure the radius if necessary in Measure Process.) |

STEP 2: Populate the MASTER TUBE DATA Grid

|

Since the Split Bend feature creates a grid based on the number of straights in the MASTER data, it is important to set the number of points that you will be measuring in the reversed tube. |

STEP 3: Configure the Split Bend Window

|

The Split Bend window is on the Bend Setup tab in the MASTER TUBE menu. Click into that window. |

|

|

In the Split Bend window, set any straight that will be treated as a Split Bend. |

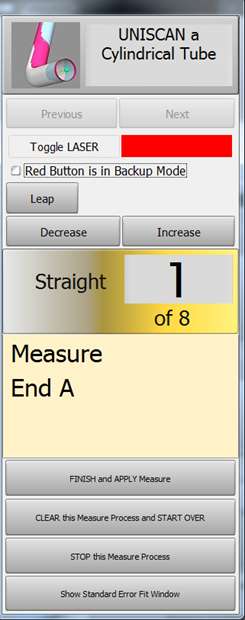

STEP 4: Measure The Part

|

This step is identical to regular reverse-engineering measuring. |

STEP 5: Choose Build Measured Tube Data Only

|

Because the MASTER data row count is greater than zero, the Measurement Complete window will offer to allow you to ALIGN the measured tube. |

|

|

The new measured tube will appear as a blue tube like this. |

STEP 6: Copy Measured to Master

|

Copy Measured to Master Data in the Data Handling menu. This will overwrite the MASTER data ZEROS with the MEASURED tube data. |

Other Pages

- Back to VTube-LASER

- See also Calibration-Leapfrog-Move Targets

- Purchase the targets at the store.