Difference between revisions of "VTube-LASER v2.6"

(→25px ENHANCED - Improved Scanned Point Cloud in Display) |

(→25px ENHANCED - Improved Scanned Point Cloud in Display) |

||

| Line 101: | Line 101: | ||

<br><br> | <br><br> | ||

| − | ==[[image:Check.jpg|25px]] ENHANCED - Improved Scanned Point Cloud in Display== | + | ==[[image:Check.jpg|25px]] ENHANCED - Improved Scanned Point Cloud in Display for FAST Redraw Speed== |

<table width=800> | <table width=800> | ||

<tr> | <tr> | ||

| Line 115: | Line 115: | ||

In order to better anticipate how to draw dense point clouds, VTube has this new field in the System Options / Graphics Setup Tab.<br><br> | In order to better anticipate how to draw dense point clouds, VTube has this new field in the System Options / Graphics Setup Tab.<br><br> | ||

This new value is multiplied against the current diameter to determine how close the displayed points should be on the screen. The default diameter factor value is 0.125. So, for example on a 2 inch OD tube, the points are displayed no closer than 0.25" on the screen. However, for a 0.25" OD tube, the point separation changes so that they display no closer than 0.031" (.25 x .125).<br><br> | This new value is multiplied against the current diameter to determine how close the displayed points should be on the screen. The default diameter factor value is 0.125. So, for example on a 2 inch OD tube, the points are displayed no closer than 0.25" on the screen. However, for a 0.25" OD tube, the point separation changes so that they display no closer than 0.031" (.25 x .125).<br><br> | ||

| + | This feature has no impact on END SCANS. | ||

</td> | </td> | ||

<td> | <td> | ||

Revision as of 23:03, 22 July 2016

|

Revision 2.6 Build 108Release Date: July 15, 2016 |

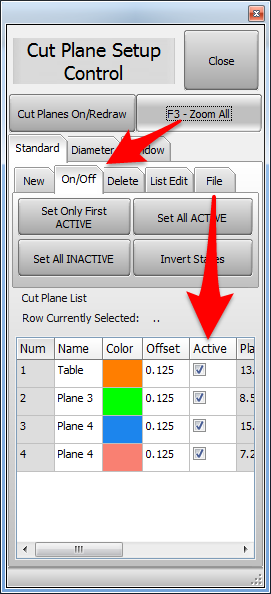

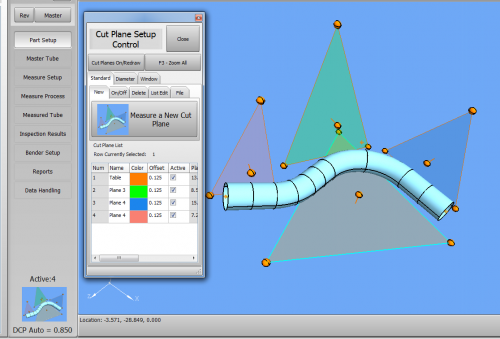

ENHANCED - CUT PLANES REDESIGNED

ENHANCED - CUT PLANES REDESIGNED

This release is all about CUT PLANES. So if you use cut planes to automatically removed points behind or around the tube, then this a very big release for you. If you have to measure tube assemblies with tubes near each other, then you will want to learn this version. If you measure tubes or wires that bend back on themselves, then this release is very important for you.

Here are the big items in this release:

1 - Use any number of MULTIPLE CUT PLANES simultaneously.

The new Cut Plane Setup Control window can be opened at any time to control any number of multiple cut planes simultaneously.

2 - CUT PLANES can now be measured ON-THE-FLY during any tube measurement.

In previous versions, the CUT PLANE measurement had to be performed before you started measuring the tube. Now you can measure new cut planes even if you are in the middle of measuring a tube - then continue where you left off after you measure a new Cut Plane.

3 - CUT PLANES can be made ACTIVE or INACTIVE at any time

The ACTIVE check boxes in the Cut Plane List let you switch them on or off at any time.

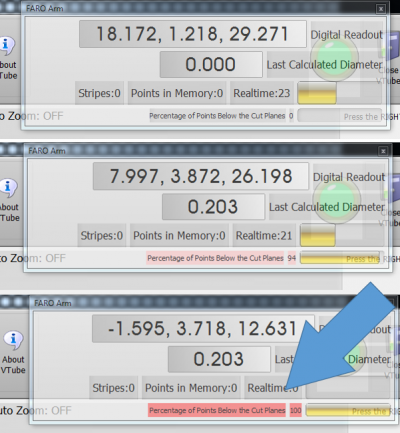

4 - The DRO (Digital Readout) shows if the scan is below the Cut Plane before you scan

Have you ever wondered why the arm wasn't measuring, only to find out that you were below the cut plane? This will give you a clear indication if you are below the cut plane - BEFORE you press the green button

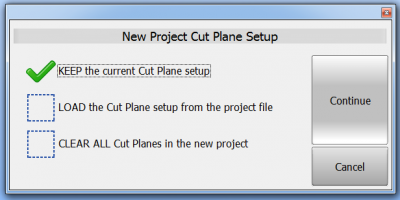

5 - CUT PLANE setups are now stored in project files

Because of this new feature, a new dialog appears when you are changing projects. This gives you the flexibility of choosing to keep the current setup, or to load the setup inside the project file.

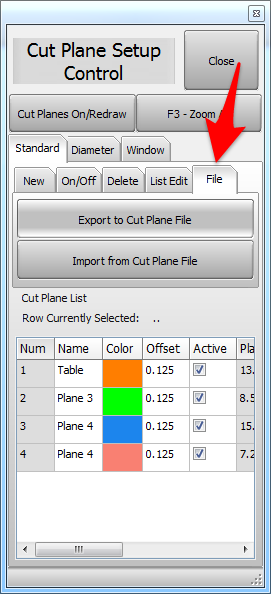

6 - The CUT PLANE setup can be exported and imported using XML files

- VTube can now export and import entire CUT PLANE setups using the XML file format.

- VTube uses XML files to store the Cut Plane setup automatically between shut down and switch on. So you no longer have to worry about losing the current Cut Plane setup when you close VTube. VTube will automatically store it for you for use in future measuring sessions. This is ideal for a majority of our customers that never change the arm or the measuring table in relationship to each other.

7 - NEW CONCEPT for Measuring Tight Parts: DIAMETER CUT PLANES

Measure Across Several Diameters - VTube will find the correct straight

This new feature lets you scan across several diameters or objects of any kind - and still AUTOMATICALLY find only the diameter you want to keep.

AIM Inc. - Wirebending Applications

The feature was developed to solve a need that we encountered at AIM Inc. when measuring wire bent parts. The orange part shown below is a sample test piece that is formed from 0.2 inch diameter wire. When measuring this part the FARO scanner stripe often crosses four straights at the same time.

Illustration of the Issue

Imagine the HD (blue) laser stripe measuring one of these four straights. In order to measure one, it is very hard to orient the beam in a way that avoids the three straights you don't intend to measure. This is the easy way to measure one of these four straights:

However, touching four straights at the same time will not allow VTube to calculate a centerline of any one of these straights - unless you use the DCP feature. The DCP feature follows some simple rules to allow VTube to sort out and select the one straight that you intend to measure - every time.

It works great on tube assemblies too - like headers for multiple tubes close to each other, and HVAC assemblies where tubes pass close to objects like evaporators.

Tutorials On How DCP Works

- See the tutorial on DCP - Diameter Cut Planes

- See How to Measure Tubes Attached to an Evaporator with the DCP Feature

ENHANCED - Improved Scanned Point Cloud in Display for FAST Redraw Speed

ENHANCED - Improved Scanned Point Cloud in Display for FAST Redraw Speed

|

Because of new features like Bend Profile scanning, VTube has to handle and display much more dense clouds than in previous versions. |

|

|

In order to better anticipate how to draw dense point clouds, VTube has this new field in the System Options / Graphics Setup Tab. |

Other Pages

- Back to VTube-LASER

- Back to VTube Software Updates (for LASER Mode)

- See also VTube-STEP

- See also VTube-STEP Revisions

- See VTube-LASER Customer Support Page to download the latest version.