Difference between revisions of "VTube-LASER Cylinder Fit Tolerances"

(→Cylinder Centerline - Accuracy) |

(→Cylinder Fit Data Window Reports Estimated Maximum Fit Deviations) |

||

| Line 36: | Line 36: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| + | After calculating a cylinder centerline from surface points, VTube-LASER also returns how well the centerline FITS the surface points of the cylinder.<br><br> | ||

VTube-LASER reports the accuracy of the centerline fit in the Cylinder Fit Data window. The values are deviations for...<br><br> | VTube-LASER reports the accuracy of the centerline fit in the Cylinder Fit Data window. The values are deviations for...<br><br> | ||

* RADIUS: Estimate the maximum deviation of half the diameter.<br><br> | * RADIUS: Estimate the maximum deviation of half the diameter.<br><br> | ||

Revision as of 17:25, 20 February 2017

|

Verify Calculations to Cylinder Centerlines

|

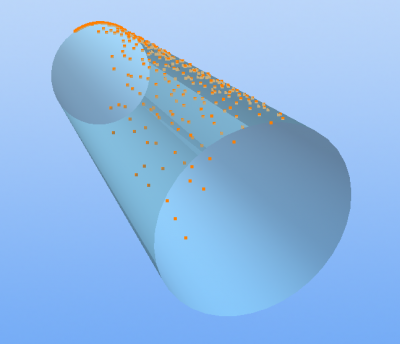

VTube-LASER uses surface points scanned with laser or measured with ball probes to calculate tube centerlines. Regular tube scans assume that the primitive shape to solve for is a cylinder. |

Cylinder Fit Data Window Reports Estimated Maximum Fit Deviations

|

After calculating a cylinder centerline from surface points, VTube-LASER also returns how well the centerline FITS the surface points of the cylinder.

These estimate values are calculated using statistical math. The values are standard deviation x 2, which means that we have 95% assurance that the these values are the maximum deviation. |

Wobble Deviation

|

To simplify terminology, we say that the highest of the X and Y values is the "wobble deviation". If the centerline calculation is very good, then wobble deviation decreases. If the calculation or fit is poor, then the wobble deviation is too high. |

Default Cylinder Fit Tolerances

|

To allow VTube-LASER to warn for poor cylinder measurements, it stores tolerances for the allowed deviations during cylinder fit. These values are often setup in the Measure 1 tab of the System Options menu. |

Recommended Aerospace Cylinder Fit Tolerances

|

Aerospace-grade materials are often very precise. For aerospace applications, we strongly recommend that you consider using tighter tolerances like these shown here. |

How to Test for Your Ideal Tolerances

|

You can test for ideal cylinder fit tolerance settings by watching the tolerance values in the Cylinder Fit window when measuring a tube. |

Other Pages

- Back to VTube-LASER

- Back to VTube-STEP