Difference between revisions of "VTube-LASER Split Bend Feature"

(→Split Bend Measuring) |

(→Split Bend Measuring) |

||

| Line 97: | Line 97: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400 > | <td width=400 > | ||

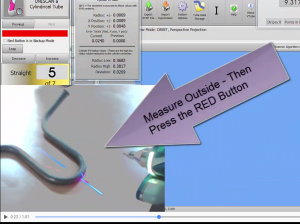

| − | During tube measurement, when you arrive at the split bend to scan, VTube-LASER will make a special sound and tell you to scan the OUTSIDE of the bend. Scan as much data as you want up to 250 stripes (250 is the default value). The goal is to be sure that at least one point in one of the stripes touches the highest point of the outside of the bend. So you can take as many stripes of data as you want - VTube will take them all in without a problem.<br><br> | + | During tube measurement, when you arrive at the split bend to scan, VTube-LASER will make a special sound and tell you to scan the OUTSIDE of the bend. Scan as much data as you want up to 250 stripes (250 is the default maximum stripe value). The goal is to be sure that at least one point in one of the stripes touches the highest point of the outside of the bend. So you can take as many stripes of data as you want - VTube will take them all in without a problem.<br><br> |

During scanning, release the green button, and look at the screen. You should see a large area of surfaces that pass the point of the outside of the bend. Press the RED button if you are finished scanning the outside and have not come to 250 stripes.<br><br> | During scanning, release the green button, and look at the screen. You should see a large area of surfaces that pass the point of the outside of the bend. Press the RED button if you are finished scanning the outside and have not come to 250 stripes.<br><br> | ||

Now scan the center of the inside. Be sure that at least one point in one stripe passes the center inside of the bend. If you are not sure, then release the green button and look at the screen to see if you have points and surfaces that appear to be in the right place. If you know you've scanned the center, then press the RED button to move on to the next straight.<br><br> | Now scan the center of the inside. Be sure that at least one point in one stripe passes the center inside of the bend. If you are not sure, then release the green button and look at the screen to see if you have points and surfaces that appear to be in the right place. If you know you've scanned the center, then press the RED button to move on to the next straight.<br><br> | ||

Revision as of 20:21, 1 May 2017

|

Contents |

About The Split Bend Feature

|

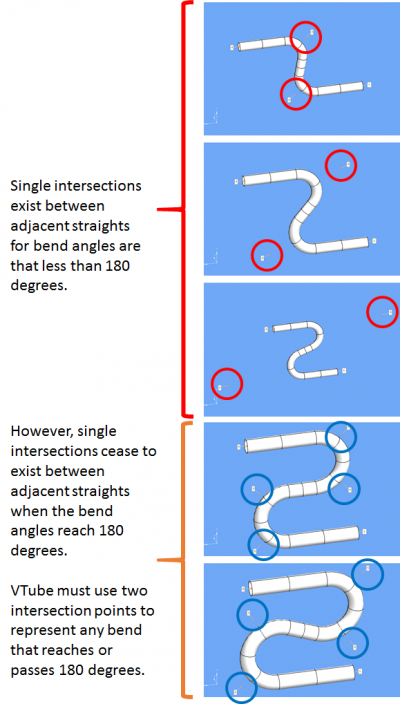

The Split Bend feature is VTube-LASER's unique method of measuring tubes with 180-degree or greater bends with accuracy.

|

Why Is Split Bend Necessary?

|

We invented Split Bend to solve a legacy measuring issue in the tube fabrication.

|

Configuring for Split Bend

|

Split Bend setup is controlled in the Bend Setup tab of the Master Tube menu in VTube-LASER, and in the Bend Setup tab in VTube-STEP. Both modes of VTube allow you to configure Split Bends. |

|

|

In the Split Bend window, set any straight that will be treated as a Split Bend. See Video 54 for how to setup for a Split Bend. |

Split Bend LRA Compression

|

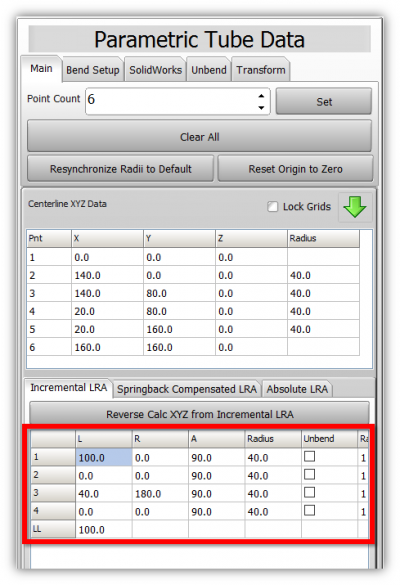

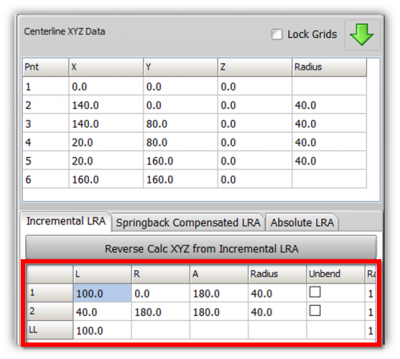

VTube-LASER knows that benders still like to refer to the 180-degree bends as a SINGLE bend. |

|

|

For this tube, we turn the Split Bend ON for straights 2 and 4, and the LRA data automatically compresses. |

Split Bend Measuring

|

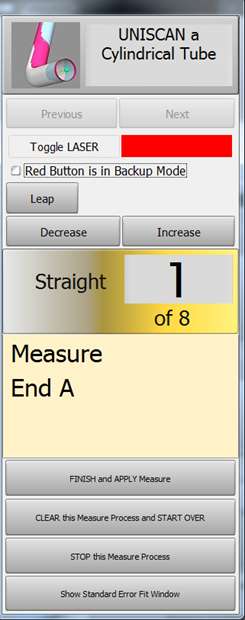

During tube measurement, when you arrive at the split bend to scan, VTube-LASER will make a special sound and tell you to scan the OUTSIDE of the bend. Scan as much data as you want up to 250 stripes (250 is the default maximum stripe value). The goal is to be sure that at least one point in one of the stripes touches the highest point of the outside of the bend. So you can take as many stripes of data as you want - VTube will take them all in without a problem.

|

Other Pages

- Back to VTube-LASER

- See also Calibration-Leapfrog-Move Targets

- Purchase the targets at the store.