Difference between revisions of "Principles of CNC Bender Data Transfer"

(→Enter the Data in CNC Bender Offline Then Save as a Part) |

(→IDEA 1: Create Supravision Data to Transfer the Master Data) |

||

| (28 intermediate revisions by one user not shown) | |||

| Line 3: | Line 3: | ||

This describes basic principles for bender data transfer to CNC Bender. | This describes basic principles for bender data transfer to CNC Bender. | ||

| − | ==Create Supravision Data to Transfer the Master Data== | + | ==IDEA 1: Create Supravision Data to Transfer the Master Data== |

| − | + | ||

<table> | <table> | ||

| + | |||

| + | <tr> | ||

| + | <td width=100> | ||

| + | |||

| + | </td> | ||

| + | <td width=300> | ||

| + | CNC Bender can import Supravision data files that contain the XYZ master data for setup of a new part | ||

| + | </td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

<tr> | <tr> | ||

| Line 16: | Line 26: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[ | + | [[image:vtube-step-1.87_screenimage.png|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 39: | Line 49: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:Cncbender xyzpage 180pipe.jpg| | + | [[Image:Cncbender xyzpage 180pipe.jpg|400px]]<br> |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 48: | Line 58: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | Press the | + | Press the '''SVin''' button button to select the Supravision file. Import the data into the XYZ page. |

</td> | </td> | ||

<td> | <td> | ||

| Line 60: | Line 70: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | Press the | + | Press the '''Calc FRB''' button to build the bender data |

</td> | </td> | ||

<td> | <td> | ||

| Line 75: | Line 85: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderFRBpage.jpg| | + | [[Image:CNCBenderFRBpage.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 81: | Line 91: | ||

</table> | </table> | ||

| + | ==IDEA 2: Enter the Data in CNC Bender Offline Then Save as a Part== | ||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=100> | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | The OFFLINE version of CNC Bender can be used to enter part data at a remote station, then save parts that are compatible with CNC Bender software. | ||

| + | </td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| − | |||

| − | |||

| − | |||

| − | |||

<tr> | <tr> | ||

| Line 98: | Line 115: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderFRBpage.jpg| | + | [[Image:CNCBenderFRBpage.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 127: | Line 144: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderSavePartFile.jpg| | + | [[Image:CNCBenderSavePartFile.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 139: | Line 156: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderMainMenu.jpg| | + | [[Image:CNCBenderMainMenu.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 163: | Line 180: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderLoadPartFileMenu.jpg| | + | [[Image:CNCBenderLoadPartFileMenu.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 176: | Line 193: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[Image:CNCBenderFRBpage.jpg| | + | [[Image:CNCBenderFRBpage.jpg|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 182: | Line 199: | ||

</table> | </table> | ||

| + | |||

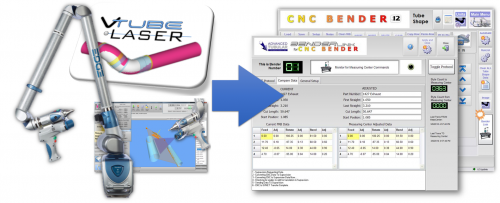

| + | ==IDEA 3: Send New Data or Corrections Data From a Measuring Center Through Benderlink== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr> | ||

| + | <td width=100> | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[Benderlink for CNC Bender]] is designed primarily as a way to connect CNC Bender to a measuring center to allow the measuring center to control the bender setup.<br><br> | ||

| + | |||

| + | It is possible to connect to any SV-Network-compatible bender, or any Eaton-Leonard-Premier compatible bender with Benderlink.<br><br> | ||

| + | |||

| + | See more here: [[Benderlink for CNC Bender]] | ||

| + | |||

| + | </td> | ||

| + | <td> | ||

| + | [[image:Cncblink_logo.jpg|500px]]<br> | ||

| + | [[image:vtube-laser_v2.2_cncbender_benderlink.png|500px]] | ||

| + | |||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | </table> | ||

| + | |||

| + | <br><br> | ||

| + | |||

| + | ==IDEA 4: Combine Ideas 1 and 2== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr> | ||

| + | <td width=100> | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | You could use SVin in CNC Bender OFFLINE at a remote engineering station to use data from outside sources to setup the bender before the data reaches the operator station. | ||

| + | |||

| + | |||

| + | </td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | ==Other Pages== | ||

| + | |||

| + | * See [[CNC Bender]] | ||

| + | * See [[CNC Bender Tutorials]] | ||

Latest revision as of 01:55, 10 May 2017

This describes basic principles for bender data transfer to CNC Bender.

Contents |

IDEA 1: Create Supravision Data to Transfer the Master Data

|

CNC Bender can import Supravision data files that contain the XYZ master data for setup of a new part |

||

|

STEP 1 |

Create the SV data file using a software package like Supravision, TubeCalc, TubeCAD, VTube-STEP or one of the Benderlink packages. If you use measuring center software like Supravision or DOCS. |

|

|

STEP 2 |

Save the file to the c:\cnc\svparts folder in CNC Bender operator station (use a thumb drive or make a direct network connection) |

|

|

STEP 3 |

In CNC Bender, go to the Tube Shape menu/XYZ tab |

|

|

STEP 4 |

Press the SVin button button to select the Supravision file. Import the data into the XYZ page. |

|

|

STEP 5 |

Press the Calc FRB button to build the bender data |

|

|

STEP 6 |

CNC Bender automatically switches to the FRB menu to display the calculated data |

IDEA 2: Enter the Data in CNC Bender Offline Then Save as a Part

|

The OFFLINE version of CNC Bender can be used to enter part data at a remote station, then save parts that are compatible with CNC Bender software. |

||

|

STEP 1 |

Enter data in the Tube Shape menu (Pre-Bend, FRB, Post-Bend). |

|

|

STEP 2 |

Press the SAVE button. |

|

|

STEP 3 |

Enter the Part name to use in the Save Part File menu and press Save.

|

|

|

STEP 4 |

Enter the File menu by pressing the File button in the main menu. |

|

|

STEP 5 |

Press the Load Part button |

|

|

STEP 6 |

Select the new part just copied and press the Load the File button. |

|

|

STEP 7 |

Finalize the setup of the bender. |

IDEA 3: Send New Data or Corrections Data From a Measuring Center Through Benderlink

|

Benderlink for CNC Bender is designed primarily as a way to connect CNC Bender to a measuring center to allow the measuring center to control the bender setup. It is possible to connect to any SV-Network-compatible bender, or any Eaton-Leonard-Premier compatible bender with Benderlink. See more here: Benderlink for CNC Bender |

IDEA 4: Combine Ideas 1 and 2

|

You could use SVin in CNC Bender OFFLINE at a remote engineering station to use data from outside sources to setup the bender before the data reaches the operator station.

|

Other Pages

- See CNC Bender

- See CNC Bender Tutorials