Difference between revisions of "VTube Overbend Calculations for Springback"

(→Justification for Using Springback Compensation) |

(→Justification for Using Springback Compensation) |

||

| (2 intermediate revisions by one user not shown) | |||

| Line 31: | Line 31: | ||

===Justification for Using Springback Compensation=== | ===Justification for Using Springback Compensation=== | ||

An increasing number of customers are asking if they should use springback compensation. Since there is a cost invested to bend and measure the test piece, each customer has a different trigger point for making springback compensation worth while.<br><br> | An increasing number of customers are asking if they should use springback compensation. Since there is a cost invested to bend and measure the test piece, each customer has a different trigger point for making springback compensation worth while.<br><br> | ||

| − | For industries with very expensive material | + | For industries with very expensive material, the justification for springback compensation is very high. For example, in nuclear shipbuilding applications, material costs of $1000 per foot require that the first part be within tolerance every time.<br><br> |

| − | + | To answer the question for your application, we recommend that you dedicate time to running time-studies to see at what point compensating for springback makes sense for your application.<br><br> | |

<br><br> | <br><br> | ||

Latest revision as of 14:42, 1 June 2016

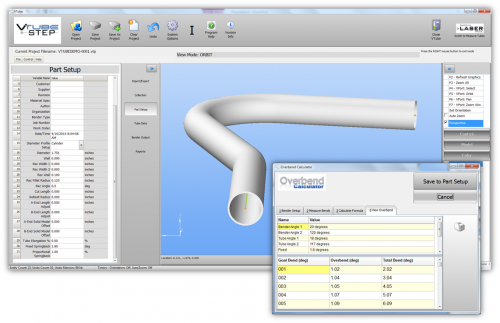

About Overbend Calculator

|

The Overbend Calculator is a built-in feature in VTube-STEP and VTube-LASER that can calculate the fixed and proportional springback values to be included in the Part Setup menu or the Springback Table. |

|

Why Use Springback Compensation with Overbending?

The springback feature is for predicting the amount of overbend necessary to compensate for springback. ("Overbend" is a term that we created and use to describe what happens in the springback compensation process. To compensate for springback, you overbend each bend.) The goal is to make the first part after the initial bender setup closer to the nominal.

Traditional Fabrication

Traditionally customers just bent the first part without any springback compensation, then allowed VTube-LASER to correct the bender to bring the part close to the master data. For customers with inexpensive material and high-volume per-part production, this was not an issue. However, now more customers are starting to build up a database of springback information to drive the part more quickly to the master shape.

The Springback Compensation Method

The method is to measure the characteristics of springback for a given material and bender setup using a test piece, then store springback values that let VTube inject extra bend angle (and remove some straight distance between bends) to get to a part within the tolerance envelope more quickly. See the steps for calculating springback values below.

Justification for Using Springback Compensation

An increasing number of customers are asking if they should use springback compensation. Since there is a cost invested to bend and measure the test piece, each customer has a different trigger point for making springback compensation worth while.

For industries with very expensive material, the justification for springback compensation is very high. For example, in nuclear shipbuilding applications, material costs of $1000 per foot require that the first part be within tolerance every time.

To answer the question for your application, we recommend that you dedicate time to running time-studies to see at what point compensating for springback makes sense for your application.

Steps to Calculate Springback Values

STEP 1Right click anywhere in the Part Setup menu and click on Overbend Calculator in the popup menu. |

|

STEP 2Set the bender to bend a two bend part.

|

|

STEP 3The actual resulting bend angles are measured and entered into the Overbend Calculator. |

|

STEP 4The proportional and fixed values are calculated and used in a springback formula to overcome springback at any angle by calculating the overbend angles.

|

Where the Values are Stored in VTube

Part SetupThe springback values are applied to the current project by storing the values in the Part Setup menu. |

|

Springback TableThe springback values can also be stored in the Springback Table so that you can reuse the values in other projects. |

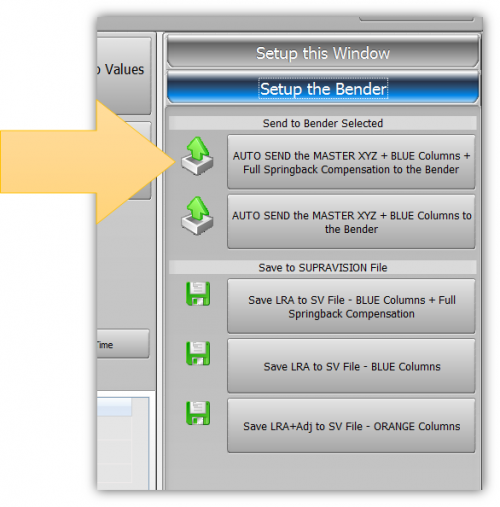

Using Springback Values in VTube-STEP to Change the Bender Setup

METHOD 1: SUPRAVISION NETWORK PROTOCOLThese two calculated values will be used to automatically calculate overbend to overcome springback when sending data to the bender in the BEND OUTPUT Automated Supravision Link protocol menu in VTube-STEP. |

|

METHOD 2: EXPORTING TO A BENDER FILEThese two calculated values will be used to automatically calculate overbend to overcome springback when saving data to a bender file in the IMPORT/EXPORT menu. |

Using Springback Values in VTube-STEP Reports

|

These two calculated values can be used to report bender with springback compensation. |

Using Springback Values in VTube-LASER to Change the Bender Setup

|

The VTube-LASER license level uses the FARO measuring center to measure and qualify a tube shape, then correct tube benders. |

Other Pages

- Back to VTube-STEP

- Back to VTube-LASER