Difference between revisions of "VTube Communication for UNISON Benders"

(→STEP 5 - PUT UNISON IN COMMUNICATIONS MODE) |

(→AVOIDANCE ROW with SLIGHTLY POSITIVE BEND ANGLE) |

||

| (54 intermediate revisions by one user not shown) | |||

| Line 8: | Line 8: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | This page describes the use of the VTube to UNISON Supravision file communications. Descriptions for VTube-STEP and VTube-LASER are included.<br><br> | + | This page describes the use of the VTube to UNISON Supravision file communications. Descriptions for communications through both VTube-STEP and VTube-LASER are included.<br><br> |

<br><br> | <br><br> | ||

| Line 19: | Line 19: | ||

__TOC__ | __TOC__ | ||

| − | =Protocol= | + | =Network Protocol= |

<table width=900> | <table width=900> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | [[VTube-STEP]] | + | The protocol used is called "Supravision Network" and runs through a standard network connection - wired or wireless.<br><br> |

| − | [[VTube-LASER]] | + | [[VTube-STEP]] uses the protocol to send new part data directly to UNISON benders.<br><br> |

| + | [[VTube-LASER]] uses the protocol to send either new part data or YBC part corrections to UNISON benders.<br><br> | ||

| + | |||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| Line 32: | Line 34: | ||

</table> | </table> | ||

| − | + | =UNISON Control Setup= | |

| − | =UNISON | + | |

<table width=900> | <table width=900> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

| − | The connection uses a standard network connection between Windows computers. | + | The connection uses a standard network connection between Windows computers. Attach the UNISON bender to a standard network to allow this kind of communication.<br><br> |

| − | + | Either share a folder on the UNISON with the VTube-LASER computer, or allow the UNISON control to gain access to a network location for READ/WRITE access.<br><br> | |

| − | Please ask UNISON | + | The most common networking method is to map a drive in the UNISON Windows system (like drive Z:) to the shared path location.<br><br> |

| + | Please ask a UNISON technician for assistance in making a connection if you need help with this setup.<br><br><br><br> | ||

==YBC --> Supravision Screen== | ==YBC --> Supravision Screen== | ||

| − | The Supravision screen in is where all communications occur. | + | The UNISON Supravision screen in is where all communications occur.<br><br>Press the measuring center button in the YBC screen to load the Supravision screen.<br><br><br> |

==Bender Number== | ==Bender Number== | ||

| − | The Supravision Network protocol requires that the bender | + | Supravision can be preconfigured for use with a network of multiple benders.<br><br> |

| + | The Supravision Network protocol requires that the bender NUMBER assigned inside the UNISON Supravision screen matches the bender number inside the VTube-LASER Bender Setup menu.<br><br>Therefore, it's important to know what bender number is being used during communications '''on both ends of the connection'''.<br><br> | ||

<br><br><br> | <br><br><br> | ||

| Line 103: | Line 106: | ||

=HOW TO SEND AND RECALL DATA FROM VTUBE-STEP AND VTUBE-LASER= | =HOW TO SEND AND RECALL DATA FROM VTUBE-STEP AND VTUBE-LASER= | ||

| − | ==[[image:vtube-step_logo_2.png|200px]] How to SEND MASTER XYZ Data to the | + | ==[[image:vtube-step_logo_2.png|200px]] How to SEND MASTER XYZ Data to the UNISON Control from VTube-STEP== |

You can import data or models into VTube-STEP then send the calculated LRA bender data to the CRIPPA bender using the VTube BENDER OUTPUT menu.<br><br> | You can import data or models into VTube-STEP then send the calculated LRA bender data to the CRIPPA bender using the VTube BENDER OUTPUT menu.<br><br> | ||

| Line 250: | Line 253: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | Bend the tube in the UNISON.<br><br> | + | Bend the tube in the UNISON bender.<br><br> |

<td> | <td> | ||

[[image:UNISON User Programming Control.png|400px]] | [[image:UNISON User Programming Control.png|400px]] | ||

| Line 268: | Line 271: | ||

<td> | <td> | ||

| + | [[image:Vtube-imc screen romer arm.png|500px]]<br><br> | ||

[[image:VTube-LASER UNISON Inspection Result.png|400px]] | [[image:VTube-LASER UNISON Inspection Result.png|400px]] | ||

</td> | </td> | ||

| Line 345: | Line 349: | ||

If you want to, it is even possible to invert the rotation direction to keep the tube from hitting the bender during rotations. | If you want to, it is even possible to invert the rotation direction to keep the tube from hitting the bender during rotations. | ||

<td> | <td> | ||

| − | [[image:VTube-LASER | + | [[image:VTube-LASER UNISON Manually Adjust Correction Values.png|400px]]<br><br> |

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | ===STEP 7 - Send the CORRECTION Values to the | + | ===STEP 7 - Send the CORRECTION Values to the UNISON=== |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | Click on AUTO SEND. This will send the ORANGE columns to the | + | Click on AUTO SEND. This will send the ORANGE columns to the UNISON bender.<br><br> |

| − | + | ||

| − | + | ||

<td> | <td> | ||

| − | [[image:VTube-LASER | + | [[image:VTube-LASER UNISON Send Orange Column Data.png|400px]]<br><br> |

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | ===STEP 8 - The SEND | + | ===STEP 8 - The SEND to BENDER Complete Window=== |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

A window should appear for a few seconds indicating that the Send to the Bender is complete.<br><br> | A window should appear for a few seconds indicating that the Send to the Bender is complete.<br><br> | ||

| + | You can allow this window to close on its own in a few seconds, or press the close button to close it immediately. | ||

<td> | <td> | ||

| − | [[image:VTube-LASER | + | [[image:VTube-LASER UNISON Send Adjusted Complete.png|400px]]<br><br> |

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | ===STEP 9 - | + | ===STEP 9 - IMPORT the Correction Data at the UNISON Control=== |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | |||

| + | <table width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=500> | ||

| + | Move to the UNISON control and follow these steps:<br><br> | ||

| + | # Be sure the SVNET01.S2B file is selected. The bender number will always be part of the filename. For example, the file for bender 9 would shown as SVFILE09.S2B<br><br> | ||

| + | # Press "Read File" button.The Read File button will import corrected data.<br><br> | ||

| + | # Observe the changed data in the Correction Data values. (It will have changed.)<br><br> | ||

| + | # Press Apply to apply the changes to the control. | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[image: | + | [[image:UNISON Read Correction.png|500px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 395: | Line 400: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | Bend the tube in | + | Bend the corrected tube starting in Step 1, then measure it again (Step 2) and follow the rest of the steps until the part is within tolerance. |

<td> | <td> | ||

| − | [[image: | + | [[image:UNISON User Programming Control.png|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | |||

| + | |||

| + | =[[image:vtube-laser_logo_1.96.png|200px]] Other TIPS for the UNISON Bender= | ||

| + | |||

| + | === AVOIDANCE ROW with SLIGHTLY POSITIVE BEND ANGLE=== | ||

| + | If you use an extra row in the bender data for an avoidance move, then it is important to know that the bend angle should be slightly positive, or the UNISON control will think that the skipped row is the LAST row. | ||

| + | [[image:vtube_laser_bendersetup_unison_smallpositive_bend.png|800px]] | ||

| + | |||

| + | <br><br> | ||

==Other Pages== | ==Other Pages== | ||

* See [[VTube-LASER]] | * See [[VTube-LASER]] | ||

* See [[VTube-STEP]] | * See [[VTube-STEP]] | ||

| − | * See [[ | + | * See [[UNISON]] for information on UNISON benders |

Latest revision as of 19:58, 17 May 2019

|

This page describes the use of the VTube to UNISON Supravision file communications. Descriptions for communications through both VTube-STEP and VTube-LASER are included. |

Network Protocol

|

The protocol used is called "Supravision Network" and runs through a standard network connection - wired or wireless. |

UNISON Control Setup

|

The connection uses a standard network connection between Windows computers. Attach the UNISON bender to a standard network to allow this kind of communication. YBC --> Supravision ScreenThe UNISON Supravision screen in is where all communications occur. Bender NumberSupravision can be preconfigured for use with a network of multiple benders. |

BENDERLINK SETUP STEPS FOR VTUBE-STEP AND VTUBE-LASER

You can perform this setup from VTube-STEP or VTube-LASER. The steps are identical in both.

STEP 1: Enter the SYSTEM OPTIONS Menu in VTube

|

STEP 2: Setup the Benderlink Network Grid for UNISON Supravision Network Protocol

|

HOW TO SEND AND RECALL DATA FROM VTUBE-STEP AND VTUBE-LASER

How to SEND MASTER XYZ Data to the UNISON Control from VTube-STEP

How to SEND MASTER XYZ Data to the UNISON Control from VTube-STEP

You can import data or models into VTube-STEP then send the calculated LRA bender data to the CRIPPA bender using the VTube BENDER OUTPUT menu.

STEP 1 - Use the BENDER OUTPUT Menu

|

STEP 2 - IMPORT the Data at the UNISON Control

|

In the YBC page, press the measuring center button. |

STEP 3 - READ NOMINAL

|

How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER

How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER

You can also send the new LRA data from the VTube-LASER BENDER SETUP menu to the UNISON bender using the VTube Bender Output menu.

|

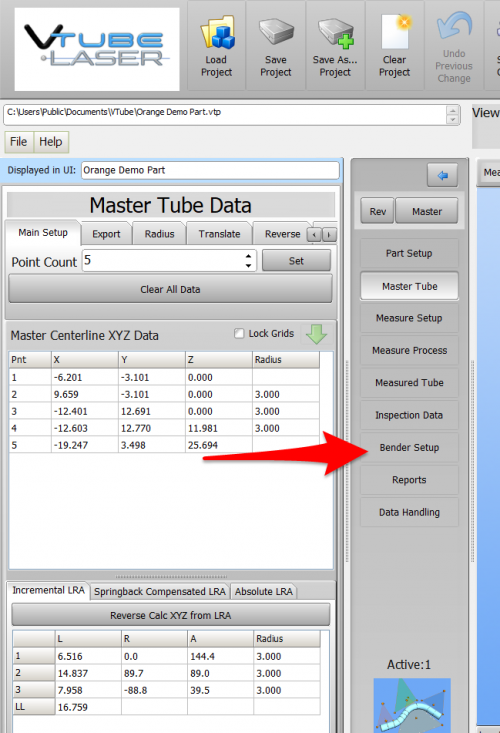

Press the "BENDER SETUP button in the Navigation Pane. |

STEP 2 - Choose the BENDER NUMBER

|

Set the correct bender number at the top of the window. |

STEP 3 - Setup the Bender Setup Data in this WINDOW

|

This is for first-time setup for a new part. Data in this window is separate from data in the main VTube-LASER window, so it is necessary to bring data into this window when performing first-time setup of a part. This ensures that the correct data is sent to the UNISON.

|

STEP 3 - Send data to the UNISON BENDER

|

STEP 4 - The Send to Bender Complete Window

|

A window indicating that data was sent should appear for a few seconds then disappear automatically. |

STEP 5 - IMPORT the Data at the UNISON Control

|

In the YBC page, press the measuring center button. |

STEP 6 - READ NOMINAL

|

How to SEND CORRECTION Data to the UNISON Control from VTube-LASER

How to SEND CORRECTION Data to the UNISON Control from VTube-LASER

STEP 1 - Bend the Tube

|

Bend the tube in the UNISON bender. |

STEP 2 - Measure the tube with VTube-LASER

|

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape. |

STEP 3 - Enter BENDER SETUP

|

Click on the BENDER SETUP button in the Navigation Pane. |

|

For dual screen systems, VTube-LASER will let you press the Switch Screens button in the upper right corner in order to move the Bender Setup window to the second screen like this: |

STEP 4 - Choose the BENDER NUMBER

|

Set the correct bender number at the top of the window. |

STEP 5 - Put the UNISON Control in COMMUNICATIONS Mode

|

Press the measuring center button in the UNISON YBC screen. |

STEP 5 - At VTube-LASER, RECALL the UNISON YBC data

|

In the Bidirectional Communication menu on the right, click on RECALL. |

STEP 6 - OPTIONAL STEP - You Can Manually Change the ADJUSTMENT Values

|

You can manually change the ADJUSTMENT values before sending corrections if you want to. Some users like to set the first and last Length adjustment to zero in order to keep the start position of the carriage in the same place - for when they have extra length on the ends. |

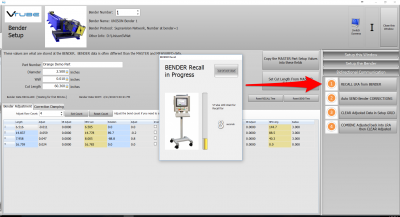

STEP 7 - Send the CORRECTION Values to the UNISON

|

Click on AUTO SEND. This will send the ORANGE columns to the UNISON bender. |

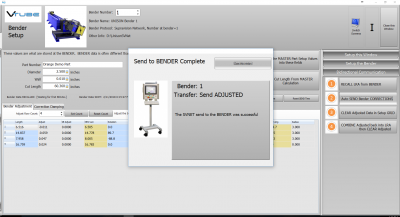

STEP 8 - The SEND to BENDER Complete Window

|

A window should appear for a few seconds indicating that the Send to the Bender is complete. |

STEP 9 - IMPORT the Correction Data at the UNISON Control

|

Move to the UNISON control and follow these steps:

|

STEP 10 - REPEAT STEPS 1 THROUGH 9

|

Bend the corrected tube starting in Step 1, then measure it again (Step 2) and follow the rest of the steps until the part is within tolerance. |

Other TIPS for the UNISON Bender

Other TIPS for the UNISON Bender

AVOIDANCE ROW with SLIGHTLY POSITIVE BEND ANGLE

If you use an extra row in the bender data for an avoidance move, then it is important to know that the bend angle should be slightly positive, or the UNISON control will think that the skipped row is the LAST row.

Other Pages

- See VTube-LASER

- See VTube-STEP

- See UNISON for information on UNISON benders