Difference between revisions of "CNC Bender General Application Errors"

(→STEP 2: Look at the top of the CALL STACKS Tab menu in the Bug Report) |

(→STEP 2: Look at the top of the CALL STACKS Tab menu in the Bug Report) |

||

| Line 65: | Line 65: | ||

<br><br> | <br><br> | ||

| − | [[image: | + | But what give you the most helpful information is the second row's function: |

| + | |||

| + | [[image:cncbender_showbugreport_callstacks_closeupfunction.jpg|450px]] | ||

==Other Pages== | ==Other Pages== | ||

*See back to [[CNC Bender Technical Notes]] | *See back to [[CNC Bender Technical Notes]] | ||

Revision as of 17:10, 23 July 2010

CNC Bender uses a powerful error reporting system that logs the details of the system and details about the error the moment they occur.

Contents |

General Application Error Dialog

This is an actual picture of the error dialog:

When the dialog displays, you can choose to do one of several steps:

- Send a bug report to us (requires an internet connection from the operator station)

- Print a bug report (if a printer is attached to the operator station)

- Show a bug report on the screen

- Continue to run the application

- Restart the application

- Close the application

Diagnosis with the Bug Report Menu

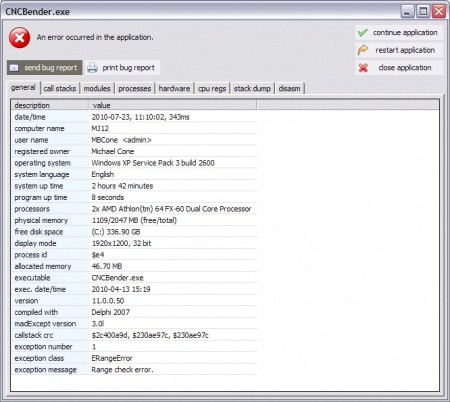

The "show bug report" button is very helpful in diagnosing errors because you can get more information about the nature of the error. We induced an error to demonstrate how this error dialog can help diagnose problems. Then we clicked on the Show Bug Report button.

This is how the bug report appears:

STEP 1: Look at the bottom of the GENERAL Tab in the Bug Report

When we click on "Show Bug Report", the first tab menu to display is "general".

The last two lines of the general bug report give immediate clues regarding the problem you are experiencing with the software.

In this case, the error has to do with "range", which is developer-speak for "a number is too big or too small somewhere." So this gives the first clue.

Next, we click on CALL STACKS tab:

The CALL STACK sounds a bit scary to non-programmers. But it's not so bad really: This is a detailed map of which procedure inside our code the error occurred. The last column called "function" and the first line shows the actual procedure that the software was running when the error occurred. Look at this example:

In this case, the error occurred inside the function UUPositionToUW. If you share this with one of the programmers from Advanced Tubular, then we will have the information necessary to track the problem. (In this case, the error is that one of the floating point values is NEGATIVE when it should not be. UUPositionToUW converts a floating point number to an integer value that MUST be positive.)

But what give you the most helpful information is the second row's function:

Other Pages

- See back to CNC Bender Technical Notes