Difference between revisions of "Benderlink for Eaton Leonard"

(→How It Works) |

|||

| Line 9: | Line 9: | ||

Benderlink communicates with a device attached to your bender called the [[Benderlink Ethernet Module]]. This module is an industrial box that contains electronics that is designed to perform direct communications through specialized electronics with Eaton Leonard benders. Each [[Benderlink Ethernet Module]] comes with both CABLE and WIRELESS capabilities. '''(This is the only WiFi technology available for legacy Eaton Leonard controls.)''' [[image:Wifi_logo.jpg]] | Benderlink communicates with a device attached to your bender called the [[Benderlink Ethernet Module]]. This module is an industrial box that contains electronics that is designed to perform direct communications through specialized electronics with Eaton Leonard benders. Each [[Benderlink Ethernet Module]] comes with both CABLE and WIRELESS capabilities. '''(This is the only WiFi technology available for legacy Eaton Leonard controls.)''' [[image:Wifi_logo.jpg]] | ||

| − | [[image:benderlink_ethernet_module_for_el.jpg]] | + | [[image:benderlink_ethernet_module_for_el.jpg|right|200px]] |

== EL Data - Offline Editing and Network Storage == | == EL Data - Offline Editing and Network Storage == | ||

Revision as of 06:57, 6 June 2007

This is a software/hardware system that allows any AICON TubeInspect measuring center to communicate with Eaton Leonard benders that use the legacy EL current loop protocol (Velog, EL-2000, Premier, and Lightspeed).

Contents |

How It Works

Benderlink communicates with a device attached to your bender called the Benderlink Ethernet Module. This module is an industrial box that contains electronics that is designed to perform direct communications through specialized electronics with Eaton Leonard benders. Each Benderlink Ethernet Module comes with both CABLE and WIRELESS capabilities. (This is the only WiFi technology available for legacy Eaton Leonard controls.)

EL Data - Offline Editing and Network Storage

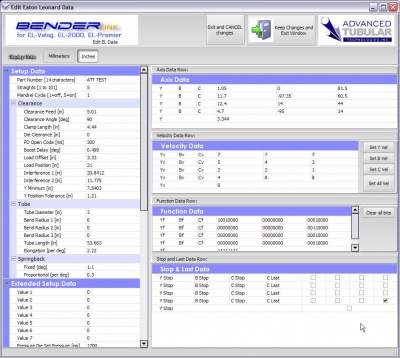

Benderlink for EL allows operators to edit ALL the Eaton Leonard data transferred to Velog, EL-2000, and Premier controls. Hundreds of EL values have been identified and are now completely editable inside the Edit EL Data window.

An easy-to-use user interface has been designed to allow operators to easily change values for Eaton Leonard benders very quickly. Examine the user interface on the right, and you will see how simple the Eaton Leonard value structure has been made. The box on the left allows for easy access to all SETUP and EXTENDED SETUP values. The values have been grouped into logical groups for easier access.

The YBC grids on the right are separated the YBC data into four groups: Axis Data, Velocity Data, Function Data, and Stop and Last Data. Editing the data is very fast because moving to the correct variable is very fast.

Data can be sent to one of up to 100 benders, or saved on a local or network drive for backup.

AICON TubeInspect

The AICON TubeInspect measuring center is a vision system that is designed to measure tubing that uses Benderlink for Eaton Leonard for communication with the legacy EL benders.

Benderlink for EL can import AICON MES (measuring center) files, and use them to correct EL benders.

REVISIONS

June 6, 2007 - Revision: Benderlink for EL v4-20070606