|

|

| Line 162: |

Line 162: |

| | <br><br><br> | | <br><br><br> |

| | | | |

| − | ====Video 107: Corrections Loop with SOCO Beckhoff Controls==== | + | ====Video: Corrections Loop with SOCO Beckhoff Controls==== |

| | | | |

| | <table width=1000> | | <table width=1000> |

Revision as of 19:44, 3 May 2022

About this Page

|

This page describes the setup and use of the VTube to SOCO communications.

The distributor of SOCO benders is TFS - Tube Form Solutions in Elkhart, Indiana.

|

|

Communications for Two SOCO Control Types

SECTION FOR BECKHOFF CONTROL TYPES

SOCO SV-M Protocol (Beckhoff Type Controls)

|

VTube-STEP can export NEW Supravision files that this control can load. In the part load section of this control, just choose any file with the $$$ filename extension, and the control will know that it is a new Supravision file to load.

VTube-LASER, the version of VTube that connects to a portable measuring center arms, can send measured data to the SOCO control for corrections.

|

|

Sending a NEW Part to the SOCO Bender (Beckhoff Type Controls)

- Connect the SOCO bender to the network using a standard Ethernet cable. Usually, SOCO computers can be accessed through the lower front of the operator station. Run the cable through the small side door on the right, and up to the computer system. The SOCO control computer will have Ethernet ports available for connection.

- Setup a shared network location either in the SOCO windows control or in a network path on your network.

- From VTube-STEP or VTube-LASER, save a Supravision file for the new part you want to send to the SOCO in that network location.

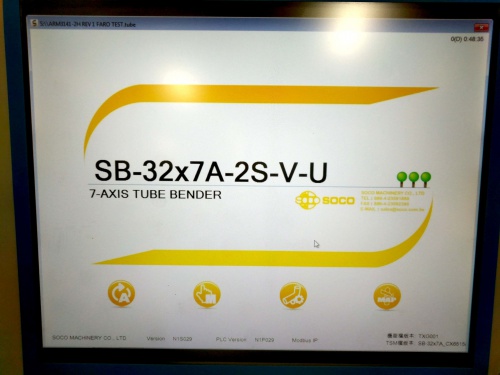

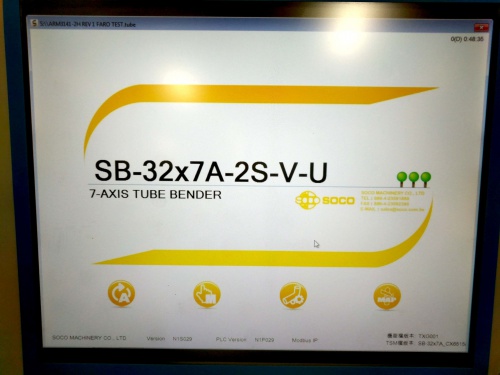

- In the SOCO Startup Screen, press the MAP button.

|

|

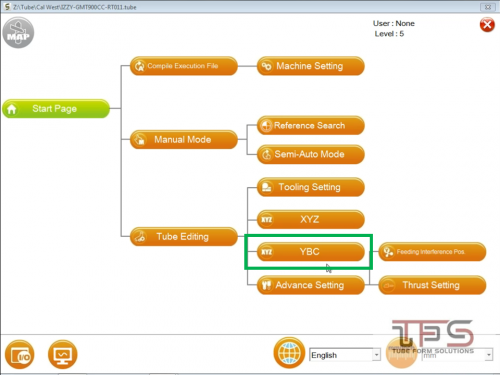

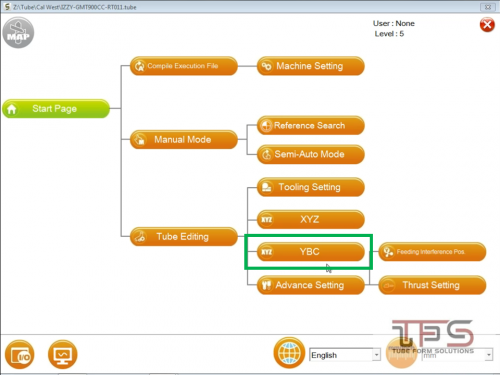

- In the SOCO MAP screen, press the YBC button.

|

|

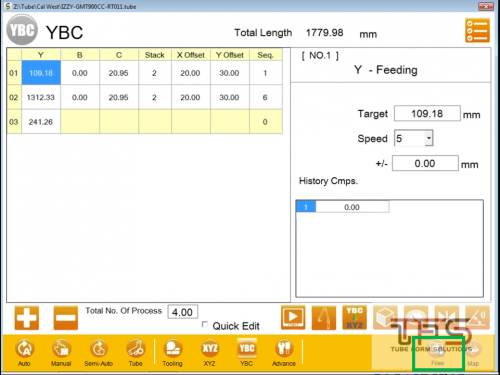

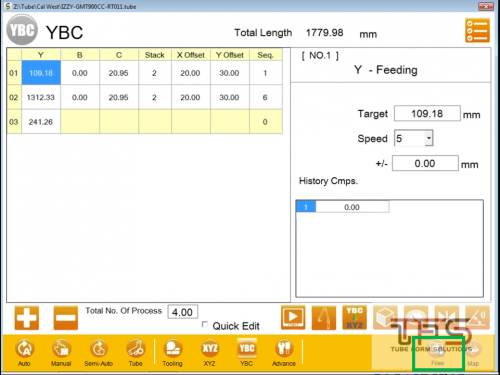

- In the SOCO YBC screen, press the FILES button.

|

|

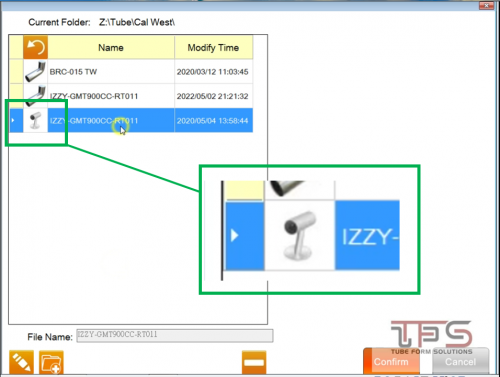

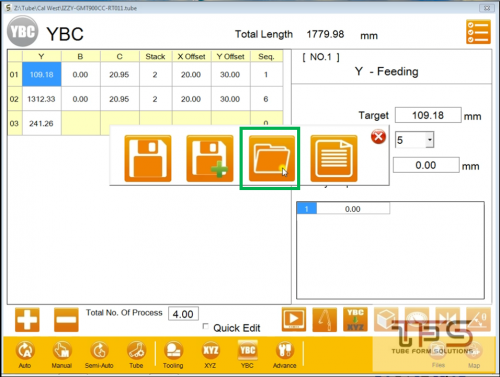

- Press the OPEN FOLDER button.

|

|

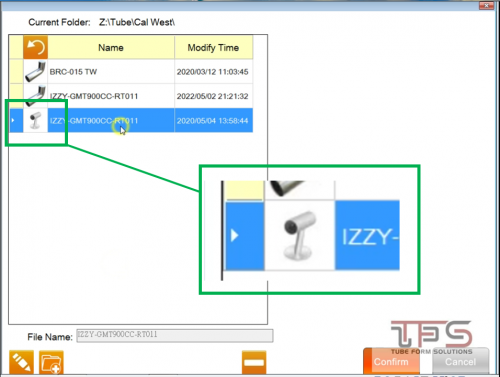

- Browse to the Supravision file. (The SOCO will show a "T" icon for a Supravision file. SOCO knows that this is a Supravision file because it has a $$$ filename extension. VTube also uses this same extension when exporting Supravision files.)

- Press the CONFIRM button.

- The new nominal YBC data will display on the screen.

|

|

You can also see a video of this process in a video in our SOCO video library.

How to Set Up and Use a Corrections Loop at the SOCO Bender (Beckhoff Type Controls)

- Connect the SOCO bender to the network using a standard Ethernet cable. Usually, SOCO computers can be accessed through the lower front of the operator station. Run the cable through the small side door on the right, and up to the computer system. The SOCO control computer will have Ethernet ports available for connection.

- Setup a shared network location either in the SOCO windows control or in a network path on your network.

- In the SOCO Startup Screen, press the MAP button.

|

|

- In the SOCO MAP screen, press the Machine Setting button.

|

|

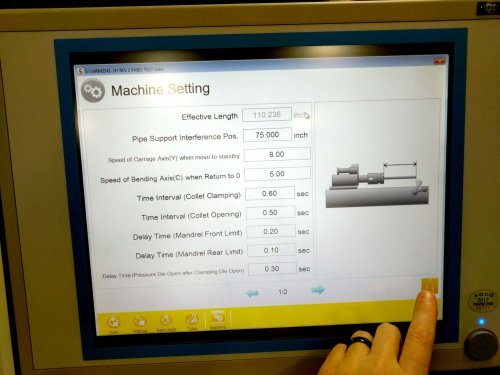

- In the SOCO Machine Setting screen, press the measuring center button.

|

|

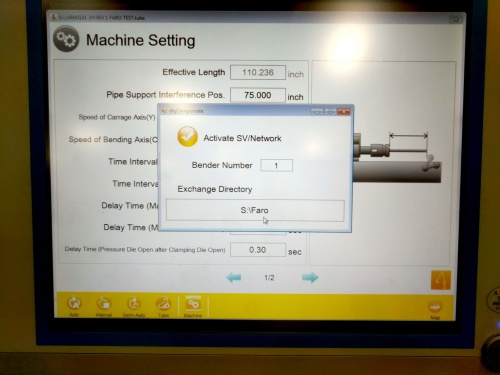

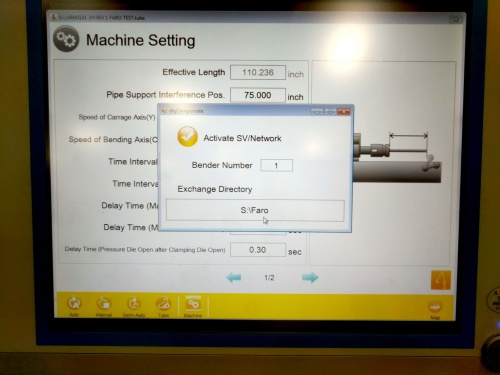

- Enter the shared network path in the Exchange Directory field. This path name cannot be a UNC name (like \\192.168.0.2\VTube\). It must be a path with a drive and a path that follows. If you must network to a location on the network, then map a drive letter to that location, and use the mapped drive letter in this field.

- Enter the bender number. Each bender number needs to have a unique number in the network. The bender number must be 1 or higher. Don't use "0" for the bender number, because VTube requires a bender number that is at least 1.

|

|

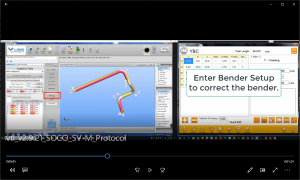

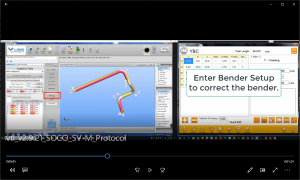

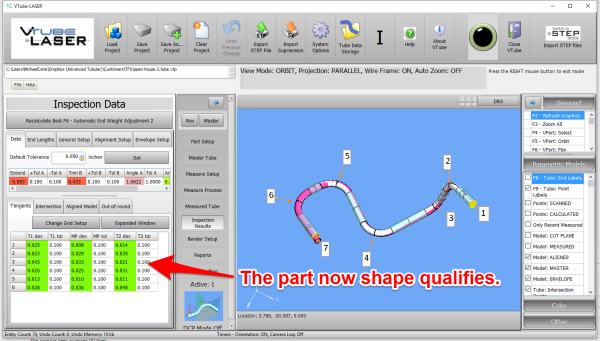

Video: Corrections Loop with SOCO Beckhoff Controls

|

This demo video shows how VTube-LASER performs corrections loop communications with SOCO Beckhoff controls.

|

|

|

How to SEND CORRECTION Data to the Beckhoff SOCO Control from VTube-LASER

|

VTube-LASER, the version of VTube that connects to a portable measuring center arms, can send measured data to the SOCO control for corrections from the Bender Setup screen.

Enter that screen and press Auto SEND. In this protocol, VTube-LASER sends the MEASURED data in the Supravision file.

|

|

How to IMPORT CORRECTION Data in the Beckhoff SOCO Control from VTube-LASER

|

At the SOCO bender, in the YBC screen, press the measuring center and import the $$$ file that was saved. The filename will have this form: SOCO-M001.$$$, or SOCO-M002.$$$, or SOCO-M003.$$$, etc., depending on the bender number.

Load that file and the SOCO will adjust the compensation data.

|

|

SECTION FOR MITSUBISHI CONTROL TYPES

SOCO SVNET Protocol (Mitsubishi Type Controls)

|

VTube-STEP can export Supravision data to Mitsubishi-based SOCO benders using the SOCO SVNet protocol.

VTube-LASER, the version of VTube that connects to a portable measuring center arms, can send measured data to the SOCO control for corrections.

|

|

Communications Setup at the SOCO Bender (Mitsubishi Type Controls)

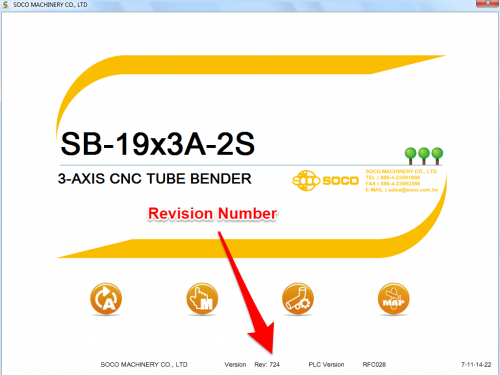

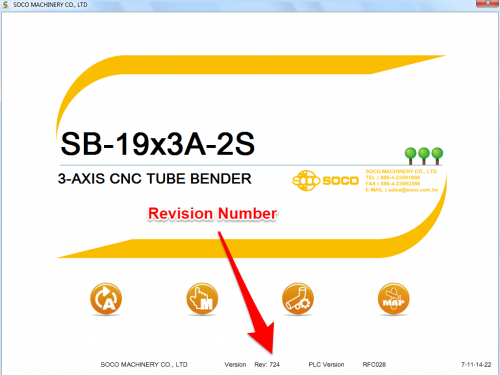

- Correct communications requires at least Revision 728 (September 10, 2016) of the SOCO software. (The control filenames include the revision number in the name like this: "NVS728.exe". The executable file is in the "c:\Program Files (x86)\Bending Machine" folder. You can see the SOCO NVC revision number also at the bottom of the startup screen (See the right image.)

- Connect the SOCO bender to the network using a standard Ethernet cable. SOCO computers can be accessed through the lower front of the operator station. Run the cable through the small side door on the right, and up to the computer system. The SOCO control computer will have Ethernet ports available for connection.

- Setup a shared network location either in the SOCO windows control or in a network path on your network.

- In the SOCO YBC screen, press the measuring center button.

- Enter the shared network path in the Exchange Directory field. This path name cannot be a UNC name (like \\192.168.0.2\VTube\). It must be a path with a drive and a path that follows. If you must network to a location on the network, then map a drive letter to that location, and use the mapped drive letter in this field.

- Enter the bender number. Each bender number needs to have a unique number in the network. The bender number must be 1 or higher. Don't use "0" for the bender number, because VTube requires a bender number that is at least 1.

- Activate the SV/SV Network communications. Touch the checkbox field until it shows a check mark (see the image on the right).

|

|

Setup Benderlink at VTube-STEP or VTube-LASER for Communications with Mitsubishi-based SOCO

Entering Benderlink Setup

- Enter the VTube System Options menu.

- Enter the Measure 2 tab menu.

- Enter the Setup Benderlink Network menu.

|

|

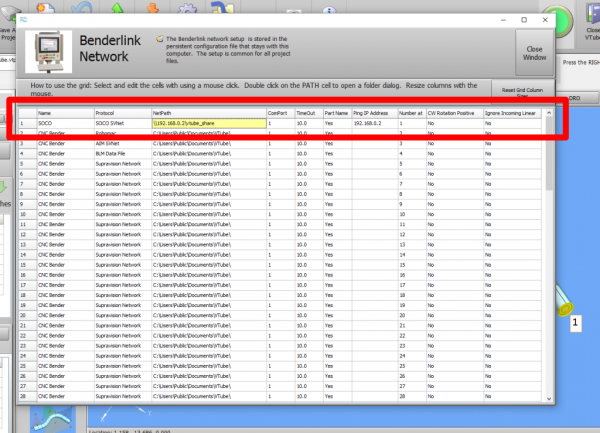

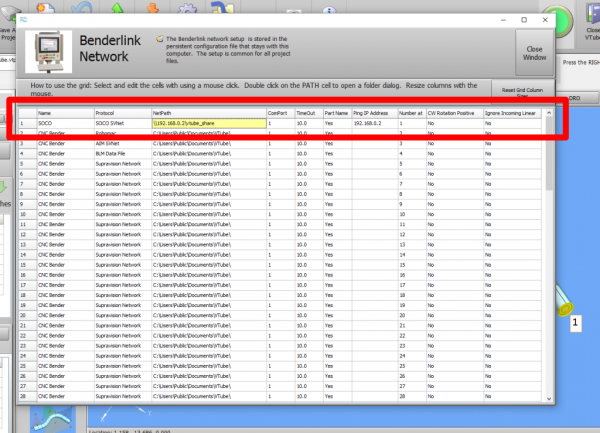

Setup the Benderlink Network Grid for the SOCO Bender

- Choose an unused row in the grid for a new SOCO bender setup. (Click on the image at the right to see a zoomed image.)

- Assign a bender name that will help operators identify what this bender is. This text will be displayed at the top of the Bender Setup menu.

- Assign the SOCO SVNet protocol.

- Enter the path to the shared drive or folder in the NetPath field. Use the same location as the SOCO setup. VTube accepts UNC names as well as regular paths with drive letters.

- Enter the IP address in the PING IP ADDRESS field if it is a fixed field. (This is not required. It allows VTube to ping the address to see if the network location is active before trying to open communications.)

- Press Close to save the settings. VTube will save these values to a persistent configuration file that will not change unless you change them in this grid.

|

|

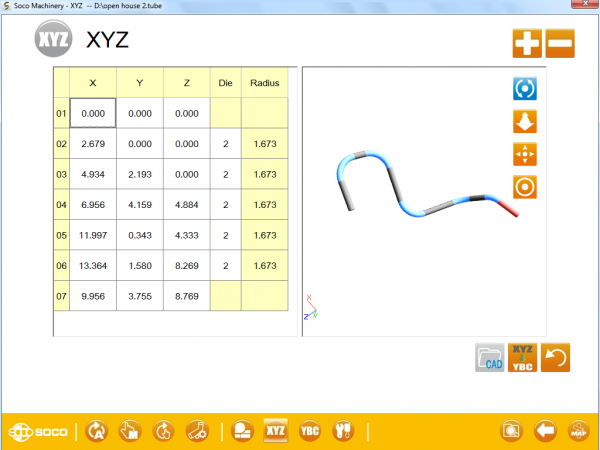

How to SEND MASTER XYZ Data to the Mitubishi SOCO Control from VTube-STEP

|

You can import data into VTube-STEP then send the XYZ Centerline data calculated to the SOCO bender using the VTube Bender Output menu.

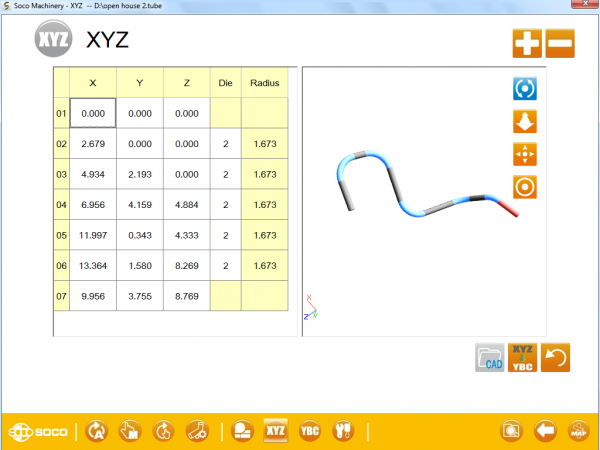

Show the XYZ Screen at the SOCO Control

At the SOCO control, to receive NEW data, you must be in the SOCO XYZ screen.

With the XYZ Screen open, the SOCO control will understand that it must extract the MASTER XYZ data in the incoming data and import that into the SOCO NVS software.

Notes:

1)

|

|

At the VTube-STEP Computer

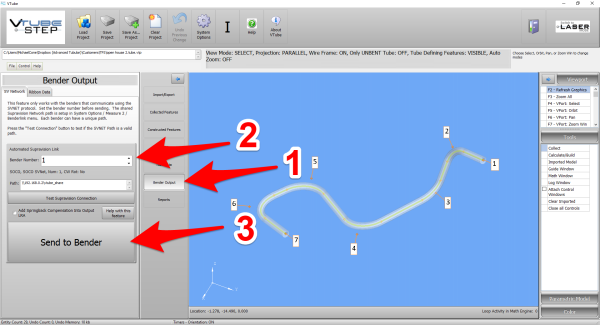

Move to the VTube-STEP computer and follow these steps to transfer the XYZ data to the SOCO.

- Press the Bender Output button in the navigation pane.

- Set the correct bender number.

- Press the Send to Bender button.

The SOCO will receive new data and ask if it should be imported with a dialog. Press YES to import the data.

|

|

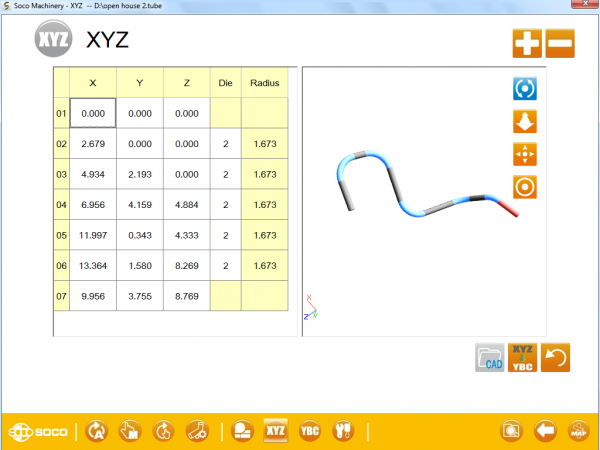

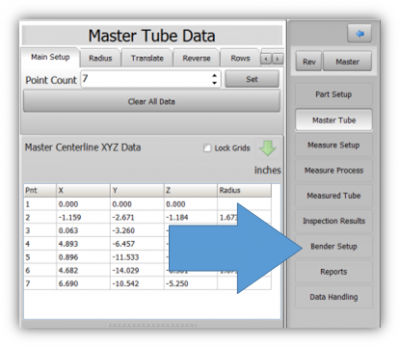

How to SEND MASTER XYZ Data to the Mitsubishi SOCO Control from VTube-LASER

|

You can also send the new XYZ Centerline data from the VTube-LASER BENDER SETUP menu to the SOCO bender using the VTube Bender Output menu.

Enter the XYZ Screen At the SOCO Control

At the SOCO control, enter the XYZ Screen. With the XYZ Screen open, the SOCO control will understand that it must extract the MASTER XYZ data in the incoming data and import that into the SOCO NVS software.

|

|

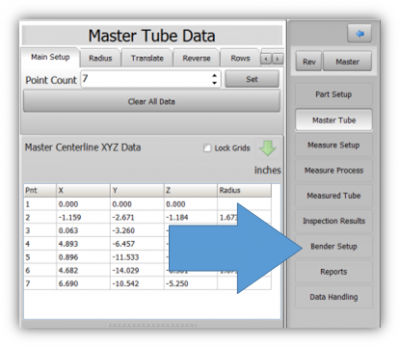

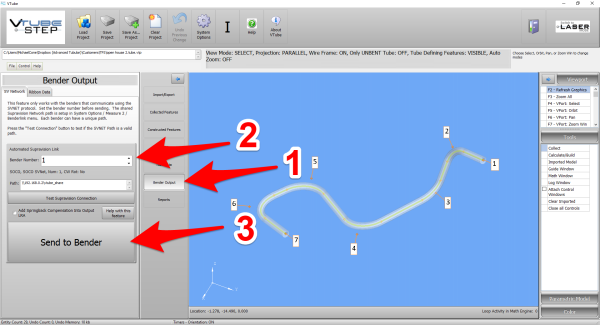

Follow these steps in the VTube-LASER:

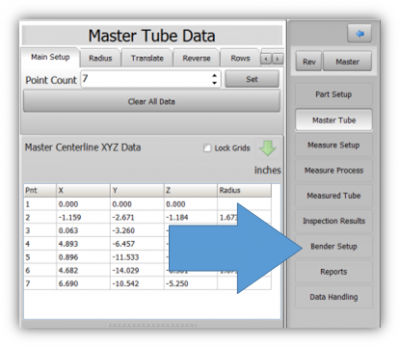

Press the "BENDER SETUP button in the Navigation Pane.

|

|

|

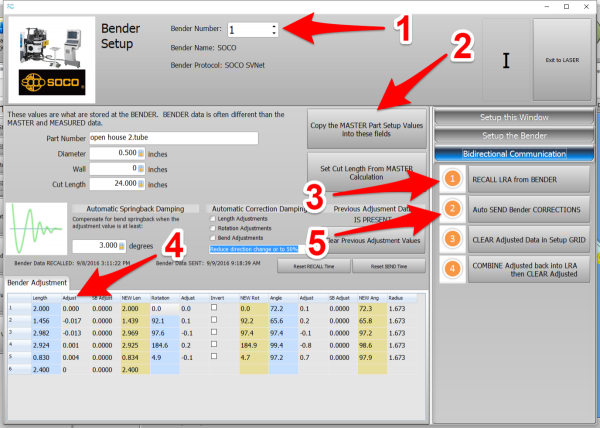

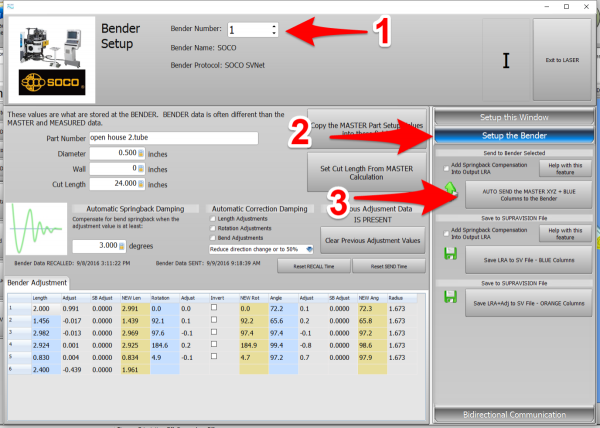

STEP 1 - Set the correct bender number at the top of the window. As of version 2.7, the SOCO SVNet option is available - which means you should see a SOCO bender at the top left corner of the screen.

STEP 2 - On the right click on "Setup the Bender".

STEP 3 - Click on AUTO SEND

The SOCO will receive new data and ask if it should be imported with a dialog. Press YES to import the data.

|

|

How to SEND CORRECTION Data to the Mitsubishi SOCO Control from VTube-LASER

At the SOCO Control

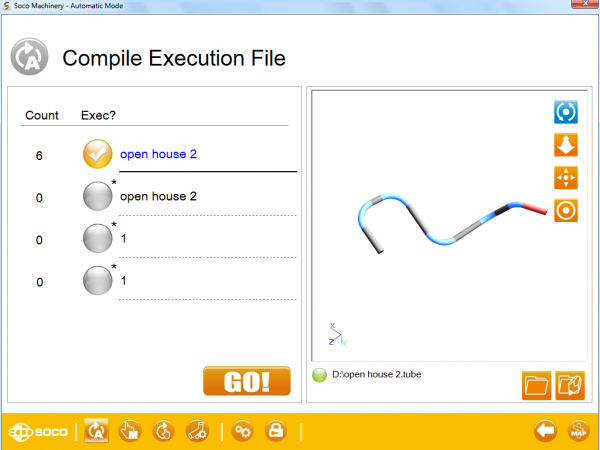

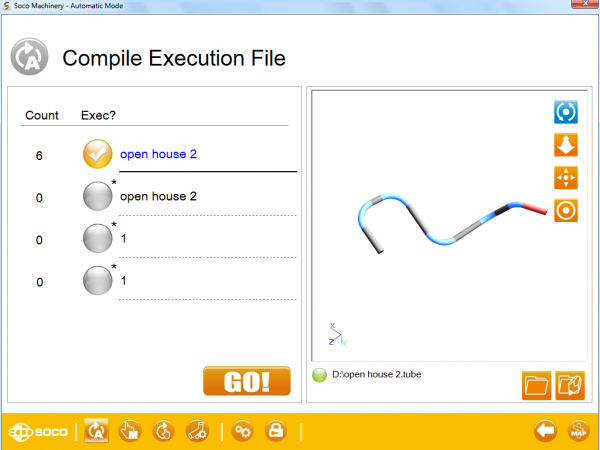

At the SOCO control, setup and bend the first tube through the YBC and then Compile Execution screen.

|

|

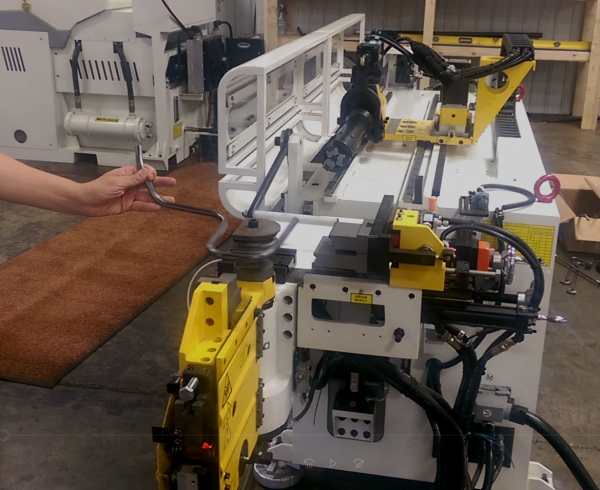

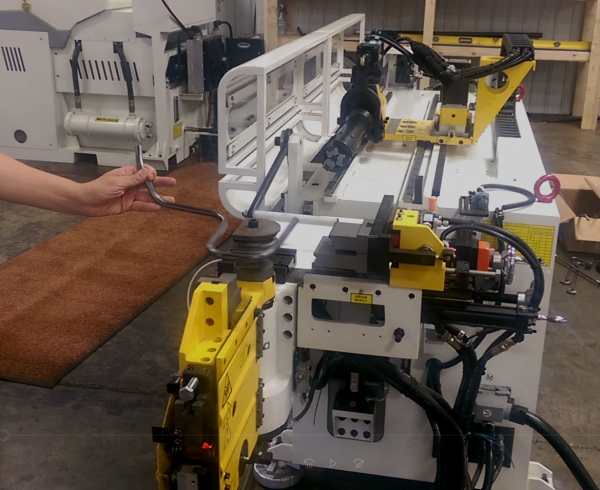

After Bending the Tube

After the bending cycle is complete, remove the tube from the dies. Leave the bender in AUTO mode.

|

|

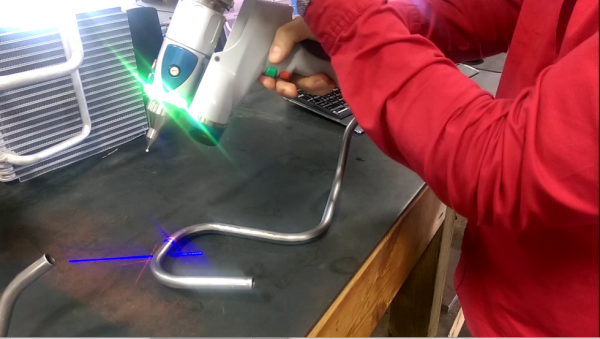

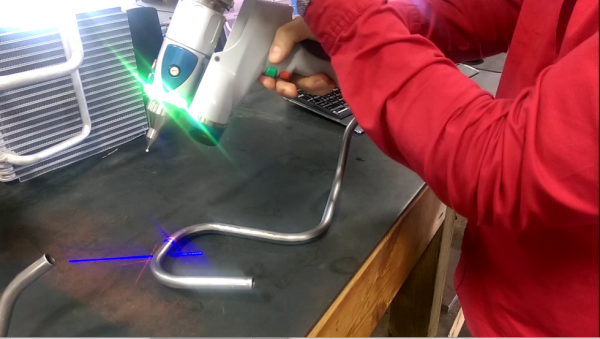

Measure the tube with VTube-LASER

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

In the VTube-LASER screen shot, you see the actual result of the first tube not qualifying in shape. The red cells in the tangent point grid on the lower left show that the measured tube centerline is out-of-tolerance.

|

|

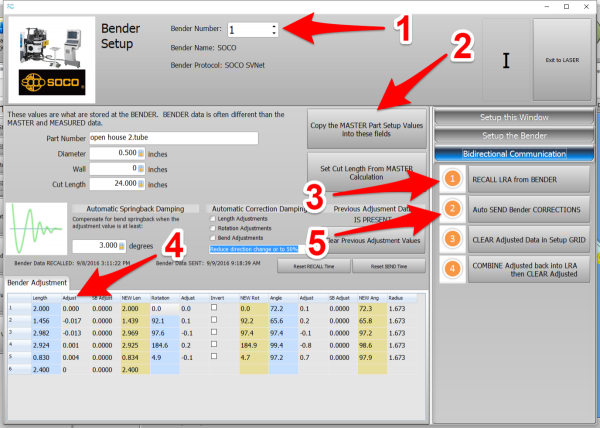

Correct the SOCO with VTube-LASER - Enter BENDER SETUP

Follow these steps in the VTube-LASER:

Press the "BENDER SETUP button in the Navigation Pane.

|

|

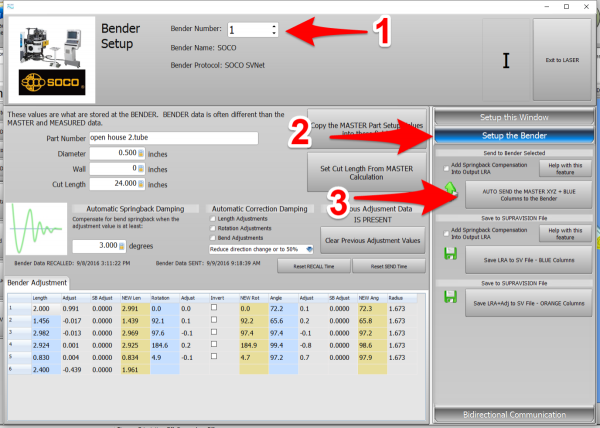

RECALL SOCO YBC data and then SEND CORRECTIONS

STEP 1 - Set the correct bender number at the top of the window. As of version 2.7, the SOCO SVNet option is available - which means you should see a SOCO bender at the top left corner of the screen.

STEP 2 - If the Part Number is empty, then press the Copy the Master Part Setup values.

STEP 3 - Click on RECALL. This will update the BLUE columns in the Bender Setup.

STEP 4 - You can manually change the ADJUSTMENT values before sending corrections. In this case, we set the first and last Length adjustment to zero in order to keep the start position of the carriage in the same place.

STEP 5 - Click on AUTO SEND. This will send the ORANGE columns to the SOCO bender.

|

|

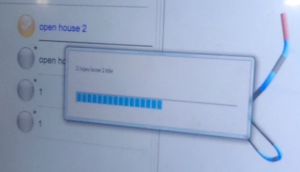

At the SOCO Bender - Press GO!

Press GO! The SOCO will compile the changes.

You will see a progress bar after you press GO!

|

|

|

The "Auto Compensation Completed" message will appear in the lower right corner.

Bend the corrected part now.

|

|

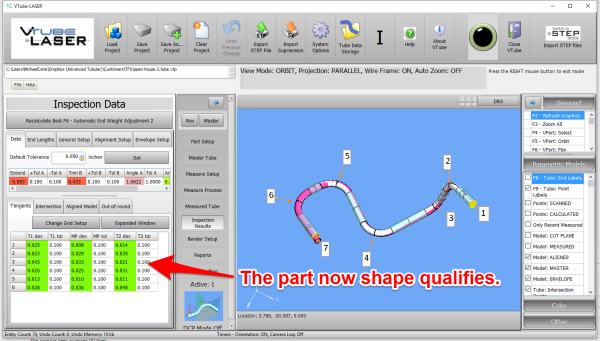

Measure at the VTube-LASER Computer

Measure and align the tube again to determine if it qualifies by falling within the envelope tolerance for the tube shape.

This screen shot shows an actual resulting change after the correction.

|

|

Other Pages