Difference between revisions of "Sigma"

(→WHY is 2 SIGMA used in VTube-LASER?) |

(→WHY is 2 SIGMA used in VTube-LASER?) |

||

| Line 47: | Line 47: | ||

| − | === | + | === 2 SIGMA and VTube-LASER SEF2 Values === |

| − | The 2 Sigma value is used quite a bit for measuring. For example, when VTube-LASER reports Cylinder Fit errors, it always shows the values as "SEF2" or "standard error fit X 2" - which is the same as 2 sigma or (2 times the sigma) value calculated. This lets you know there is a 95% chance that the error or deviation reported in the Cylinder Fit window will not exceed that value. | + | The 2 Sigma value is used quite a bit for measuring. For example, when VTube-LASER reports Cylinder Fit errors, it always shows the values as "''SEF2''" or "''standard error fit X 2''" - which is the same as 2 sigma or (2 times the sigma) value calculated. This lets you know there is a 95% chance that the error or deviation reported in the Cylinder Fit window will not exceed that value. |

[[image:vtube-laser_1_58_cylinderfit_highlight.jpg|500px]] | [[image:vtube-laser_1_58_cylinderfit_highlight.jpg|500px]] | ||

Revision as of 00:10, 4 October 2011

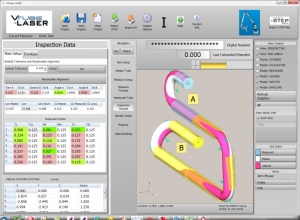

SIGMA and ERRORSBack to VTube-LASER |

Contents |

|

Most have heard of the "bell curve" in mathematics. This is the shape that describes the probability that a given percentage of measurements will fall within a certain region under a standard bell curve. This shape is found in nature - so its one that mathematicians use often. This shape of the standard bell curve is called "Normal Distribution" or "Gausian Distribution." |

HOW SIGMA PERTAINS to the BELL CURVE

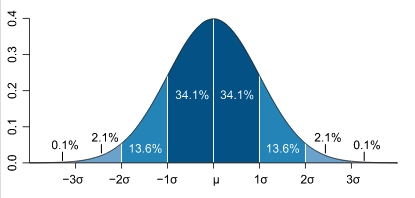

A statistical measurement called "standard deviation" is also referred to as "sigma" on the horizontal axis of a bell curve. Basically, this is a measurement of how much the measurements vary from the center value by a distance of a value called "sigma" on either side of the center of the curve.

1 SIGMA - 68% Chance

If someone says that an error is 1 sigma, then that person is referring to the greatest possible error in between the lines marked with - 1 sigma to + 1 sigma in the bell curve (see the curve above). Add the percentages of the two regions under the bell to get about 68%. There is a 68% chance that the error will not exceed the value stated.

2 SIGMA - 95% Chance

If someone says that an error is 2 sigma, then that person is referring to the greatest possible error in between the lines marked with -2 sigma to +2 sigma in the bell curve (see the curve above). Add the percentages of the four regions under the bell between the - and + sigma lines to get about 95%. There is a 95% chance that the error will not exceed the value stated.

3 SIGMA - 99.6% Chance

If someone says that an error is 3 sigma, then that person is referring to the greatest possible error in between the lines marked with -3 sigma to +3 sigma in the bell curve (see the curve above). Add the percentages of the six regions under the bell to get over 99%. There is a 99.6% chance that the error will not exceed the value stated.

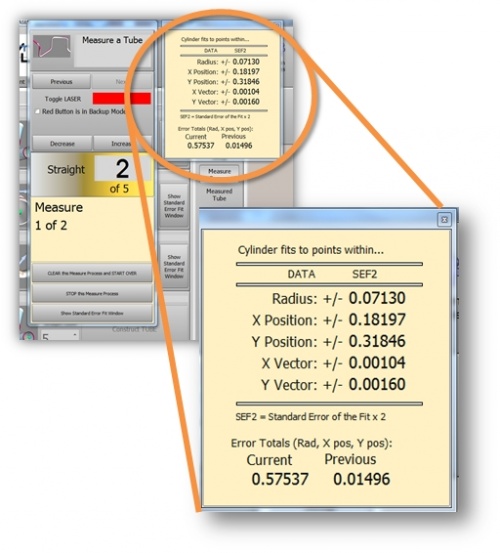

2 SIGMA and VTube-LASER SEF2 Values

The 2 Sigma value is used quite a bit for measuring. For example, when VTube-LASER reports Cylinder Fit errors, it always shows the values as "SEF2" or "standard error fit X 2" - which is the same as 2 sigma or (2 times the sigma) value calculated. This lets you know there is a 95% chance that the error or deviation reported in the Cylinder Fit window will not exceed that value.