Difference between revisions of "CRIPPA"

(→VTube-LASER Support for Crippa Bender Setup and Corrections) |

(→Success Story for a Customer that uses VTube-LASER with a CRIPPA Bender) |

||

| Line 60: | Line 60: | ||

During their initial training sessions, the customer bent a part on the bender based on the nominal setup data that was entered into VTube-LASER, then transferred to the bender.<br><br> | During their initial training sessions, the customer bent a part on the bender based on the nominal setup data that was entered into VTube-LASER, then transferred to the bender.<br><br> | ||

The operator used VTube-LASER on a FARO arm to measure and prove that the part had a maximum deviation of 0.060" of deviation along the centerline profile. The centerline profile tolerance, per the print, was from 0.030 inches up to 0.050 inches for this aerospace part - so it was necessary to send a correction to the bender.<br><br> | The operator used VTube-LASER on a FARO arm to measure and prove that the part had a maximum deviation of 0.060" of deviation along the centerline profile. The centerline profile tolerance, per the print, was from 0.030 inches up to 0.050 inches for this aerospace part - so it was necessary to send a correction to the bender.<br><br> | ||

| − | The first correction reduced the profile deviations so that only one deviation peaked at 0.012 inches. All the other deviations where half that value or better. The End-A length deviation was | + | The first correction reduced the profile deviations so that only one deviation peaked at 0.012 inches. All the other deviations where half that value or better. The End-A length deviation was 0.000 inches, and the bending technician trimmed the other end using the "End-B Trim" value in the VTube-LASER inspection page. He remeasured the final part which was confirmed to be completely inside tolerance.<br><br> |

Aerospace Welding is very happy with this system.<br><br> | Aerospace Welding is very happy with this system.<br><br> | ||

===Customer Contact Information=== | ===Customer Contact Information=== | ||

Revision as of 22:27, 20 January 2016

| CRIPPA benders are built in Italy and marketed worldwide. Customers report that they like these benders very much. They are often all electric with all actuators servo-controlled. |

Contents |

CRIPPA UII Control software

|

The CRIPPA Windows software allows for complete programming of bender setup. |

VTube-LASER Support for Crippa Bender Setup and Corrections

|

VTube-LASER communicates with the CRIPPA UII software using the Supravision Network protocol. |

Success Story for a Customer that uses VTube-LASER with a CRIPPA Bender

|

Aerospace Welding, Inc., is a Montreal-based fully-certified fabrication company for major aerospace companies. |

|

|

They use VTube-LASER running on a FARO arm to setup and correct an all electric CRIPPA bender. Customer Contact InformationNino Buttino, Directeur Commercial (Commercial Director) |

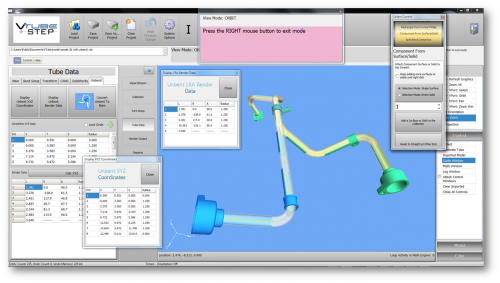

VTube-STEP Support for CRIPPA Bender SPF Files

|

VTube-STEP can export Crippa export capability allows for easy export to Crippa UII software. The format is a text file that is compatible with most Crippa benders that were released in early 2012 and on.

|

Contact Information

CRIPPA USA Distributor

Chris Harrison

Tube Process Technology LLC

4343 SKUSA DR

BRIGHTON, MI 48116

Phone (810) 599-1972

E-Mail: [email protected]

Other Pages

- See the Crippa Web Site

- See VTube-LASER

- See VTube-STEP