VTube-LASER Cylinder Fit Tolerances

|

Why Do We Need Cylinder Fit Tolerances?

|

VTube-LASER uses scanned surface points to calculate tube centerlines. |

The Cylinder Fit Data Window Reports How Well the Centerline Fits the Surface Data

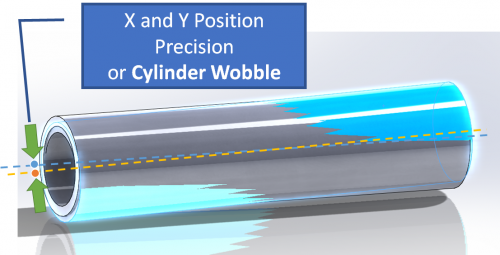

Cylinder Wobble - The highest of the X or Y values

|

To simplify visualizing the X and Y positions, we say that the highest of the X and Y values is the "cylinder wobble". The cylinder wobble in the example on the right is 0.21 inches - because it is the higher of the two values. |

Cylinder Fit Tolerances

|

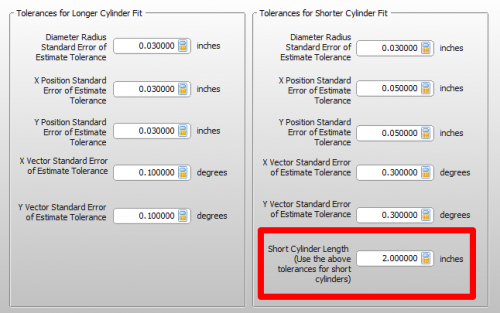

VTube-LASER uses tolerance values to decide when to warn you about potentially poor cylinder measurements. |

Default Values

|

The default values are designed as a good starting point in the VTube-LASER setup. They are excellent for quite demonstrations of the software, and work great for tubes that have a lot of deformation in the straights. |

Lower Aerospace-Grade Cylinder Fit Tolerances

|

Aerospace-grade materials are more precise compared to other applications. For aerospace applications, we recommend that you use tighter tolerances like the ones shown here. |

Why Are There Separate Values for Shorter Straights?

|

Math engines cannot calculate short straights as accurately as long straights. This has to do with the nature of cylinder math. It's a common issue with all measuring centers. Because of this, we know that VTube needs to be more patient with when fitting a cylinder centerline when the straight length is below a certain value. |

Other Pages

- Back to VTube-LASER

- Back to VTube-STEP