|

This page describes the use of the VTube to UNISON Supravision file communications. Descriptions for communications through both VTube-STEP and VTube-LASER are included.

|

|

Network Protocol

|

The protocol used is called "Supravision Network" and runs through a standard network connection - wired or wireless.

VTube-STEP uses the protocol to send new part data directly to UNISON benders.

VTube-LASER uses the protocol to send either new part data or YBC part corrections to UNISON benders.

|

|

UNISON Control Setup

|

The connection uses a standard network connection between Windows computers. Attach the UNISON bender to a standard network to allow this kind of communication.

Either share a folder on the UNISON with the VTube-LASER computer, or allow the UNISON control to gain access to a network location for READ/WRITE access.

The most common networking method is to map a drive in the UNISON Windows system (like drive Z:) to the shared path location.

Please ask a UNISON technician for assistance in making a connection if you need help with this setup.

YBC --> Supravision Screen

The UNISON Supravision screen in is where all communications occur.

Press the measuring center button in the YBC screen to load the Supravision screen.

Bender Number

Supravision can be preconfigured for use with a network of multiple benders.

The Supravision Network protocol requires that the bender NUMBER assigned inside the UNISON Supravision screen matches the bender number inside the VTube-LASER Bender Setup menu.

Therefore, it's important to know what bender number is being used during communications on both ends of the connection.

|

|

BENDERLINK SETUP STEPS FOR VTUBE-STEP AND VTUBE-LASER

You can perform this setup from VTube-STEP or VTube-LASER. The steps are identical in both.

- Load VTube.

- Click on Systems Options in the toolbar at the top of the screen.

- Enter the Measure 2 tab menu.

- Enter the Setup Benderlink Network menu.

|

|

STEP 2: Setup the Benderlink Network Grid for UNISON Supravision Network Protocol

- Choose an unused row in the grid for a new UNISON bender setup.

- Assign a bender name that will help operators identify which bender this is. This text will be displayed at the top of the Bender Setup menu.

- Assign the Supravision Network protocol.

- Enter the path to the shared drive or folder in the NetPath field. This path should point to the UNISON folder that will receive command files from VTube. (The value shown on the screen is only an example.)

- Enter the IP address in the PING IP ADDRESS field if it is a fixed field. (This is not required. It allows VTube to ping the address to see if the network location is active before trying to open communications.)

- If the UNISON rotates the Clockwise positive, then select YES in the CW Rotation Positive cell.

- The "Ignore Incoming Linear Unit" setting is optional. This will not allow the UNISON to change the linear units in VTube-LASER if they are different.

- Press Close to save the settings. VTube will save these values to a persistent configuration file that will not change unless you change them in this grid.

|

|

HOW TO SEND AND RECALL DATA FROM VTUBE-STEP AND VTUBE-LASER

How to SEND MASTER XYZ Data to the CRIPPA Control from VTube-STEP

How to SEND MASTER XYZ Data to the CRIPPA Control from VTube-STEP

You can import data or models into VTube-STEP then send the calculated LRA bender data to the CRIPPA bender using the VTube BENDER OUTPUT menu.

- The BENDER OUTPUT menu can be loaded from the NAVIGATION PANE. Inside that menu...

- Select the bender number.

- Click on "Send to Bender"

- The Send to Bender Complete window will appear. This means that VTube has dropped the data file in the location where the UNISON control can automatically load the file and its data into UII.

|

|

STEP 2 - IMPORT the Data at the UNISON Control

|

In the YBC page, press the measuring center button.

|

|

STEP 3 - READ NOMINAL

- Select the file that VTube-STEP just built. (You will need to find it on the network.)

- Press "Read Nominals" button

|

|

How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER

How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER

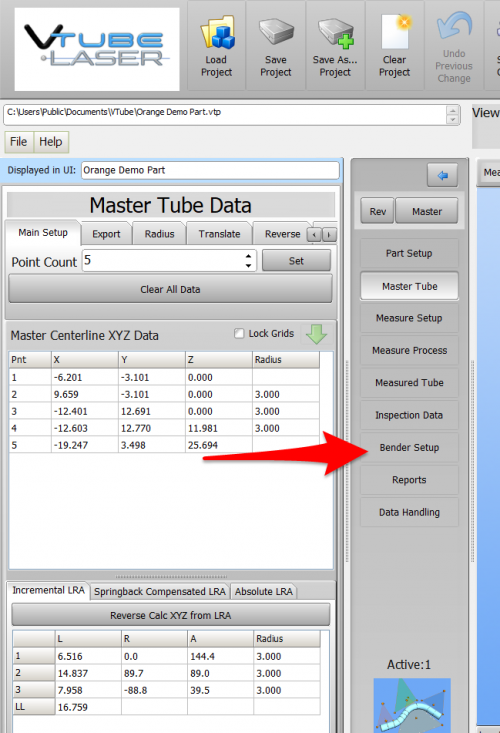

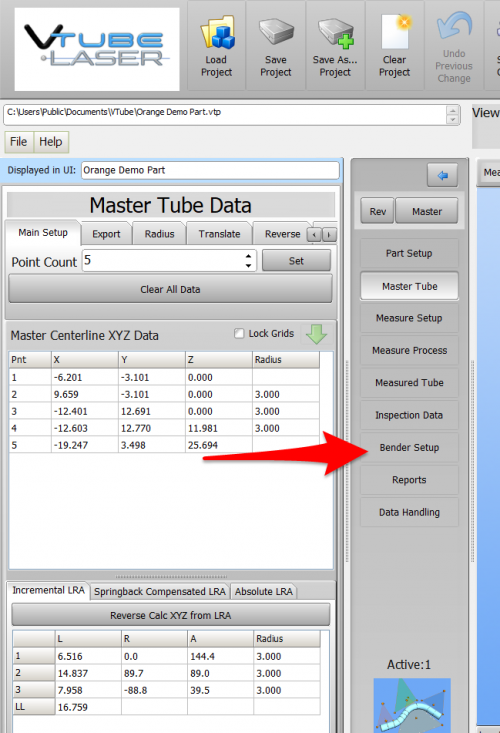

You can also send the new LRA data from the VTube-LASER BENDER SETUP menu to the UNISON bender using the VTube Bender Output menu.

|

Press the "BENDER SETUP button in the Navigation Pane.

|

|

STEP 2 - Choose the BENDER NUMBER

|

Set the correct bender number at the top of the window.

You can select up to 100 different benders.

The Bender Protocol should say "Supravision Network". (This assumes that you have already configured VTube's Benderlink in the Systems Options as described in the previous VTube-STEP section.)

|

|

STEP 3 - Setup the Bender Setup Data in this WINDOW

|

This is for first-time setup for a new part. Data in this window is separate from data in the main VTube-LASER window, so it is necessary to bring data into this window when performing first-time setup of a part. This ensures that the correct data is sent to the UNISON.

- Click on "Setup this Window" in the expanding menu on the right.

- Click on copy MASTER LRA to SETUP LRA.

- Be sure every field in the top panel has data that you want to send to the UNISON.

- The blue columns below will eventually be converted to new YBC data at the bender. So check for numbers there.

|

|

STEP 3 - Send data to the UNISON BENDER

- Click on "Setup the Bender" in the expanding menu on the right.

- Click on "AUTO SEND the MASTER XYZ + BLUE Columns to the Bender".

|

|

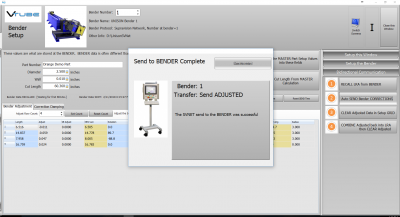

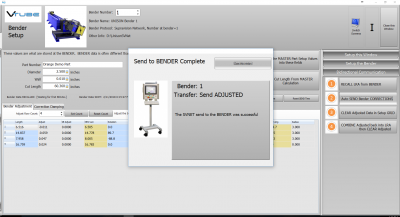

STEP 4 - The Send to Bender Complete Window

|

A window indicating that data was sent should appear for a few seconds then disappear automatically.

|

|

STEP 5 - IMPORT the Data at the UNISON Control

|

In the YBC page, press the measuring center button.

|

|

STEP 6 - READ NOMINAL

- Select the file that VTube-LASER just built. (You will need to find it on the network.)

- Press "Read Nominals" button

|

|

How to SEND CORRECTION Data to the UNISON Control from VTube-LASER

How to SEND CORRECTION Data to the UNISON Control from VTube-LASER

STEP 1 - Bend the Tube

|

Bend the tube in the UNISON bender.

|

|

STEP 2 - Measure the tube with VTube-LASER

|

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

In the screen shot on the right, the red on the top left shows that the first END "A" LENGTH is out of tolerance.

Also, the red cells in the tangent point grid show that the measured tube centerline shape is out-of-tolerance.

Also - VTube is very visual. The solid model on the right shows exactly where the part is out is exceeding the tolerance.

Click on the image to zoom in to see the values.

|

|

STEP 3 - Enter BENDER SETUP

|

Click on the BENDER SETUP button in the Navigation Pane.

|

|

|

For dual screen systems, VTube-LASER will let you press the Switch Screens button in the upper right corner in order to move the Bender Setup window to the second screen like this:

See VTube-LASER Multiple Screen Support for more information about this feature.

|

|

STEP 4 - Choose the BENDER NUMBER

|

Set the correct bender number at the top of the window.

You can select up to 100 different benders.

The Bender Protocol should say "Supravision Network". (This assumes that you have already configured VTube's Benderlink in the Systems Options as described in the previous VTube-STEP section.)

|

|

STEP 5 - Put the UNISON Control in COMMUNICATIONS Mode

|

Press the measuring center button in the UNISON YBC screen.

You should now see the UNISON Supravision screen.

Check to be sure that the bender number is correct.

|

|

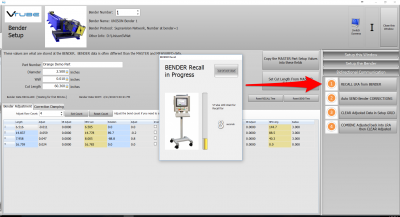

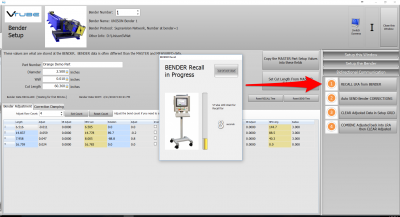

STEP 5 - At VTube-LASER, RECALL the UNISON YBC data

|

In the Bidirectional Communication menu on the right, click on RECALL.

RECALLING data is a critical step during correction. If a RECALL is not performed before a CORRECTION, then VTube may not be able make adjustments to the correct starting YBC data. Be sure to perform this step before performing the CORRECTION step below.

Important Note about UNISON benders: UNISON benders return whatever data is in memory. They do not attempt find the part on the UNISON disk based on the VTube-LASER part number. Whatever part is in the UNISON will be returned to VTube-LASER.

|

|

STEP 6 - OPTIONAL STEP - You Can Manually Change the ADJUSTMENT Values

|

You can manually change the ADJUSTMENT values before sending corrections if you want to. Some users like to set the first and last Length adjustment to zero in order to keep the start position of the carriage in the same place - for when they have extra length on the ends.

If you want to, it is even possible to invert the rotation direction to keep the tube from hitting the bender during rotations.

|

|

STEP 7 - Send the CORRECTION Values to the UNISON

|

Click on AUTO SEND. This will send the ORANGE columns to the UNISON bender.

|

|

STEP 8 - The SEND to BENDER Complete Window

|

A window should appear for a few seconds indicating that the Send to the Bender is complete.

|

|

STEP 9 - IMPORT the Correction Data at the UNISON Control

- Be sure the SVNET01.S2B file is selected. The bender number will always be part of the filename. Bender 10 would shown as SVFILE10.S2B

- Press "Read File" button.The Read File button will import corrected data.

- Observe the changed data in the Correction Data values. (It will have changed.)

- Press Apply to apply the changes to the control.

|

|

STEP 10 - REPEAT STEPS 1 THROUGH 9

|

Bend the tube again (Step 1) then measure it again (Step 2) and follow the rest of the steps until the part is within tolerance.

|

|

Other Pages

How to SEND MASTER XYZ Data to the CRIPPA Control from VTube-STEP

How to SEND MASTER XYZ Data to the CRIPPA Control from VTube-STEP How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER

How to SEND MASTER LRA Data to the UNISON Control from VTube-LASER How to SEND CORRECTION Data to the UNISON Control from VTube-LASER

How to SEND CORRECTION Data to the UNISON Control from VTube-LASER